View All IPG Photonics Laser Products —VISIT CORPORATE WEBSITE✕

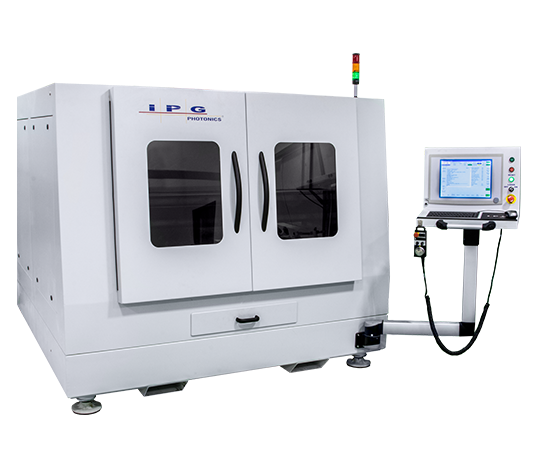

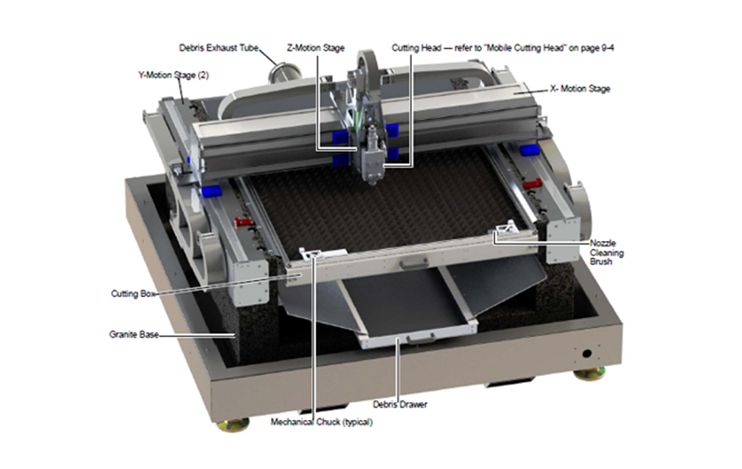

LaserCube

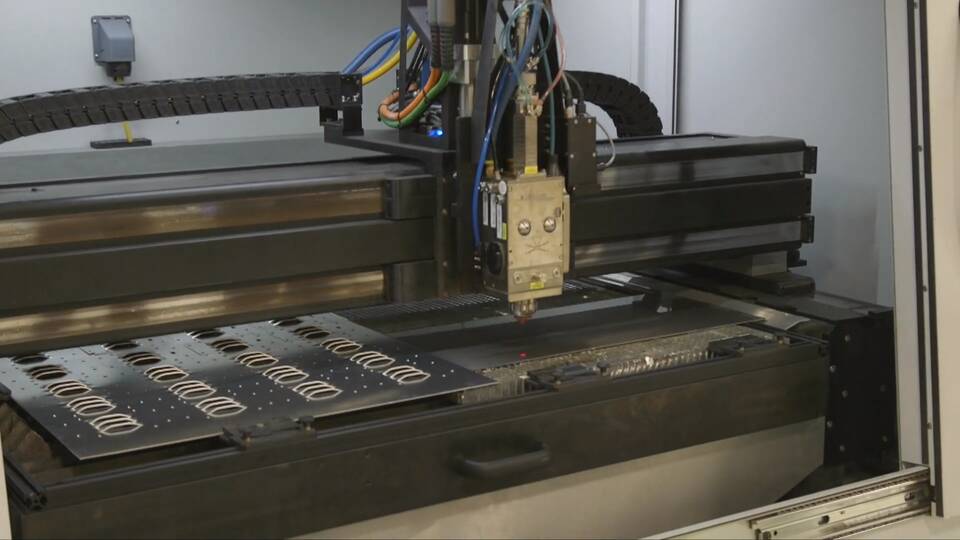

4×4 Flatbed Laser Cutting Machine

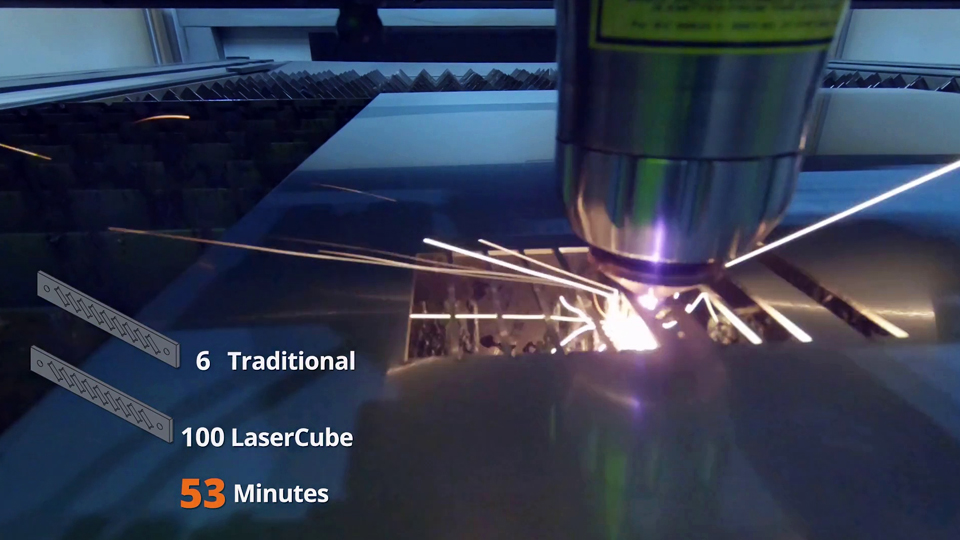

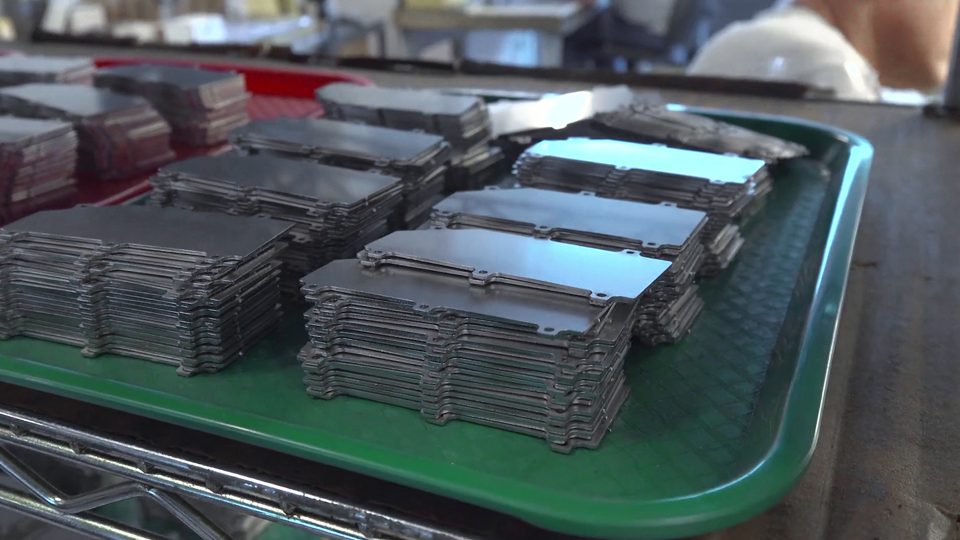

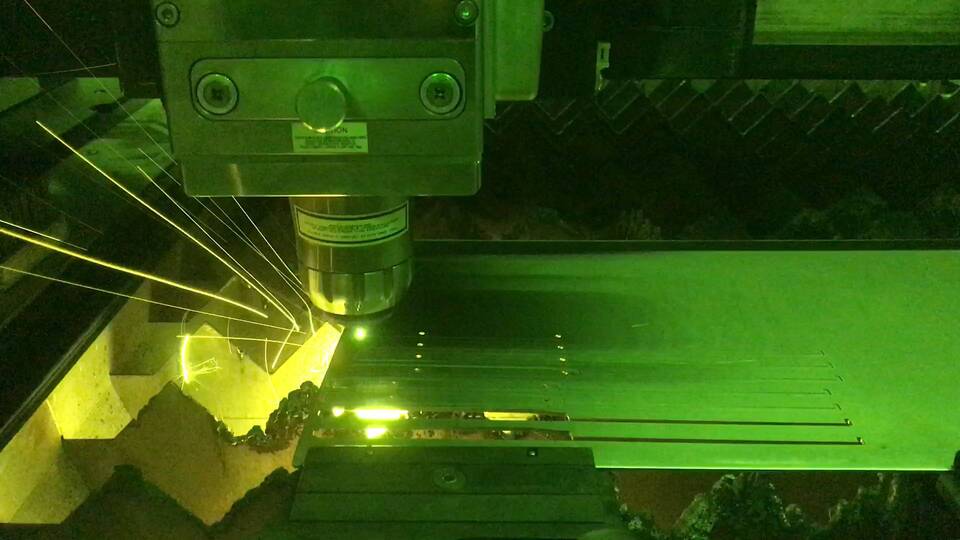

The LaserCube flatbed fiber laser cutting system is designed and optimized for fast and reliable precision cutting of small parts. The LaserCube flatbed laser cutting system is easy to use, quick and economical to install and can align with pre-punched or printed parts. Maximize productivity and lower the cost per part with a flexible laser cutting system in a small footprint.

The Right Solution For Your Shop Floor

- Widest choice of laser power to match the application

- Granite base for thermal and mechanical stability essential for high-precision cutting

- Linear motor drives provide high acceleration and minimize maintenance

- Vision registration option for punched or printed parts

- Zero-maintenance lasers and high-reliability design ensure high tool availability

- Small footprint minimizes space requirements and makes installation easy

- Library of standard recipes to begin cutting immediately

Download Datasheet

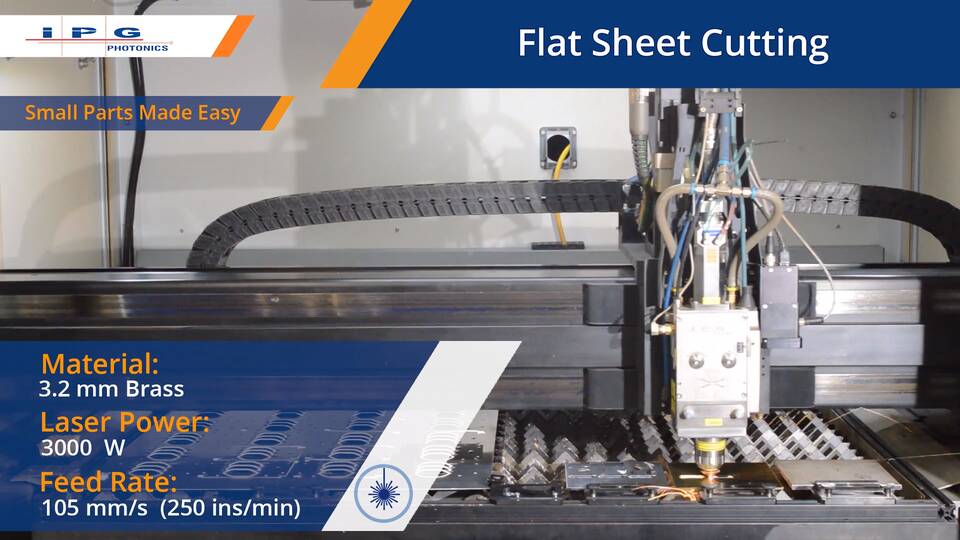

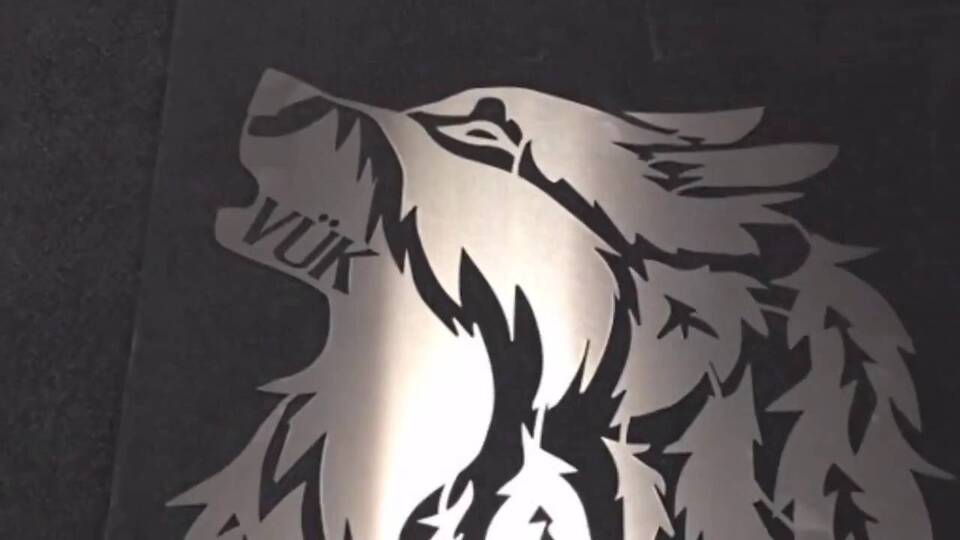

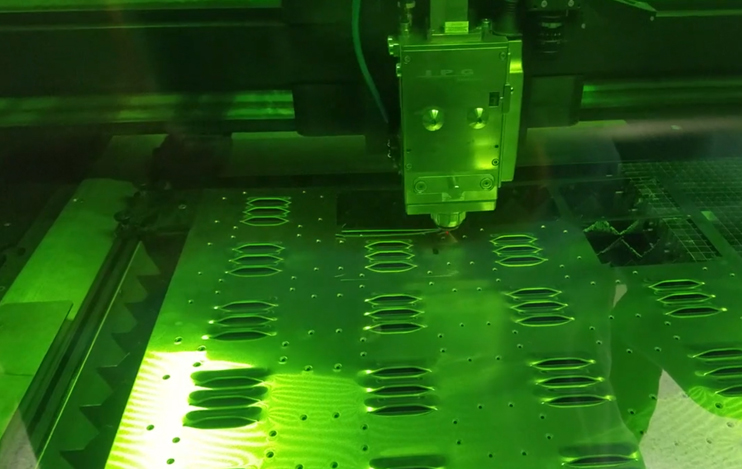

LaserCube Applications: Cutting

"Fiber lasers are changing the way our customers do business by lowering the cost of doing business"

Small Format Laser Cutting System

- Small Footprint

- High-speed cutting

- Compatible with all metal types

- Vision, rotary and automation options

- Easy to install and operate

- Virtually maintenance-free

Contact Your Local LaserCube Engineer

Transform Your Business

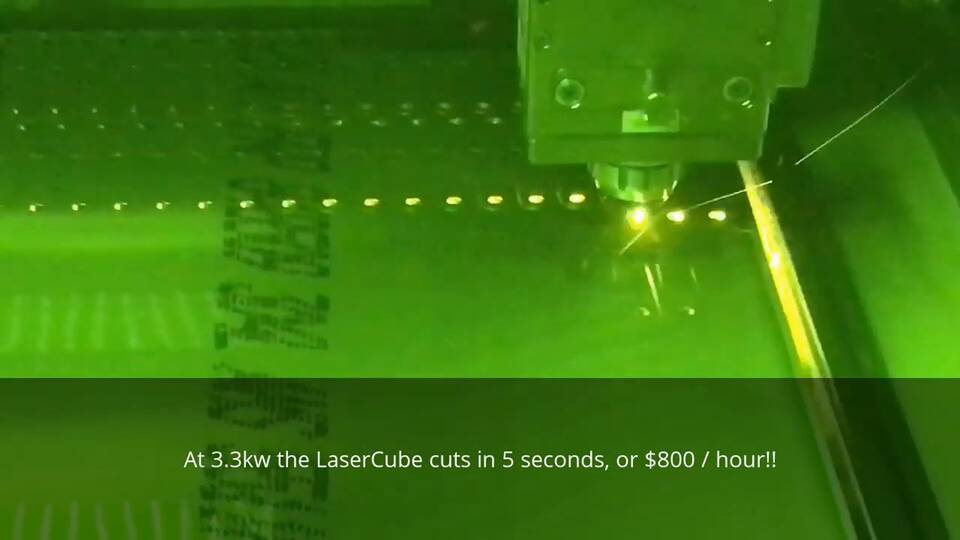

The LaserCube flatbed laser cutting system is highly affordable with the widest choice of fiber lasers available on a cutting system. Precision cutting for the most demanding jobs and the speed to make the parts quickly.

Dramatically reduce the cost per part with higher yields and overcome the traditional challenges of cutting small parts.

IPG Fiber Lasers – The Heart of the LaserCube

- Zero-maintenance – no gases to replace, no mirrors to align, no consumables and no downtime

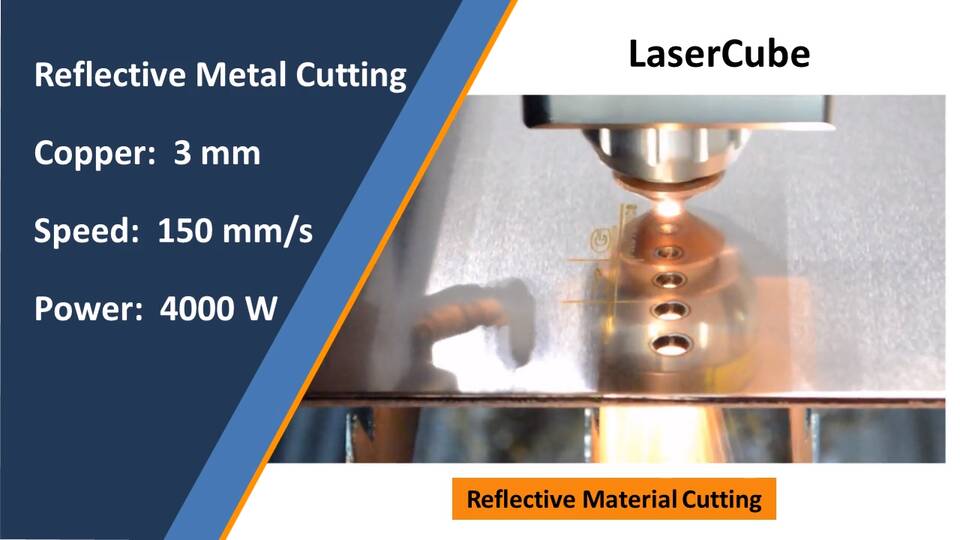

- Highly focusable 1070 nm beam couples easily and cuts fast even on reflective metals

- High Peak Power option provides 2x peak power for faster and cleaner piercing to begin cutting faster and reduce material waste

- The best laser warranty in the industry

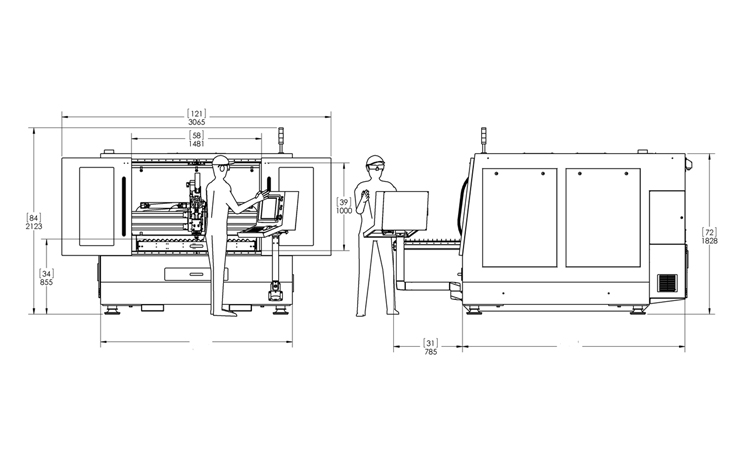

Small Footprint

LaserCube flatbed laser cutting system is a highly productive, small-format laser cutter that takes the minimum amount of floorspace in any workshop

- Requiring only 5.7 m2 (61 ft2) for the cutting workstation

- IPG fiber lasers up to 3000 W can be mounted within the workstation cabinet

- Lasers up to 700 W can be air cooled – no external chiller required

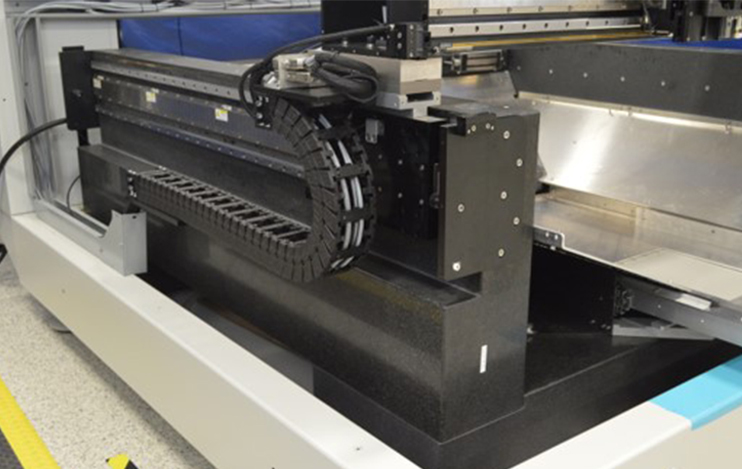

Linear Motor

The LaserCube high-force direct drive linear motors eliminate common wear issues that can impact other flatbed laser cutting system machines as they age:

- Non-contact magnetic drive – no parts to wear or replace

- Stator motor integrated with the granite base

-

Entirely solid-state drives with optical encoders for position accuracy

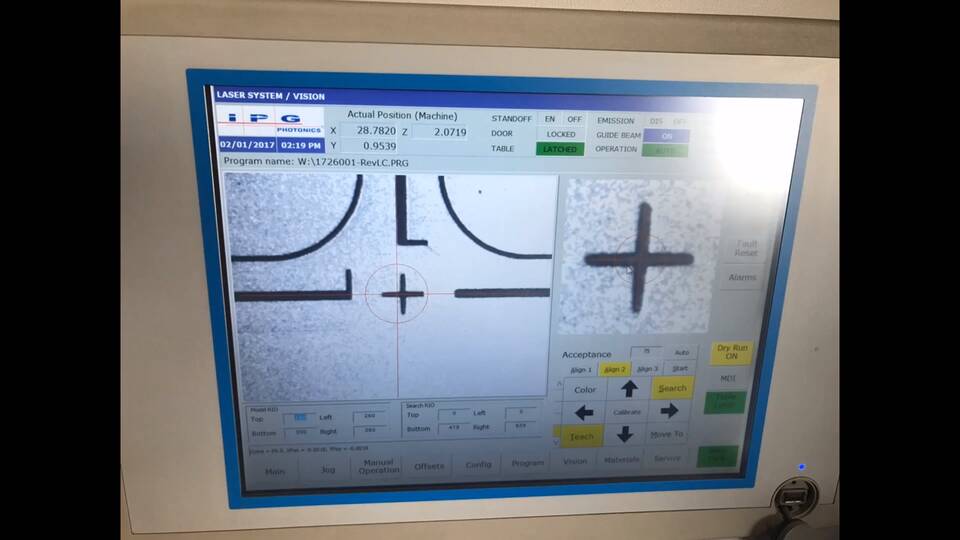

Vision Registration

The LaserCube flatbed laser cutting system can be equipped with an optional vision system to improve yields and reduce errors when cutting pre-processed parts:

- Ideal for applications that involve cutting out parts from pre-patterned or pre-processed materials such as screen-printed labels, punched parts, or chemically etched components

- Eliminates the effects of dimensional deviations

- Easy-to-use fully-automated alignment

- Laser-punch combo capability when used with an existing punch press

Granite Base

The LaserCube flatbed laser cutting system includes a natural granite base for long-term stability and ensures high-precision cutting:

- Granite is precision ground to high tolerances

- Provides vibration dampening and structure stiffness

- Large thermal mass and low coefficient of thermal expansion

- Naturally stress-relieved structure

| Laser Power, W | CW: up to 6000 |

| Beam Delivery |

FLC-30 Purged Cutting Head

|

| Work Envelope |

X: 1225 mm (48.2 in) |

| Maximum Speed: Cutting |

1000 mm/sec |

| Accuracy: Positioning Repeatability |

±25 μm (0.001 in) Positioning Accuracy |

| Motion Platform |

X-Y Linear Stage |

| Materials | Stainless/ Mild Steel, Aluminum, Brass, Copper, Laminated Foils |

| Controls/Interface |

Industrial Motion Controller, Full Look-Ahead Contouring Capability |

| Process Gas | Programmable Assist Gas Regulator – Up to 3 Gas Inputs |

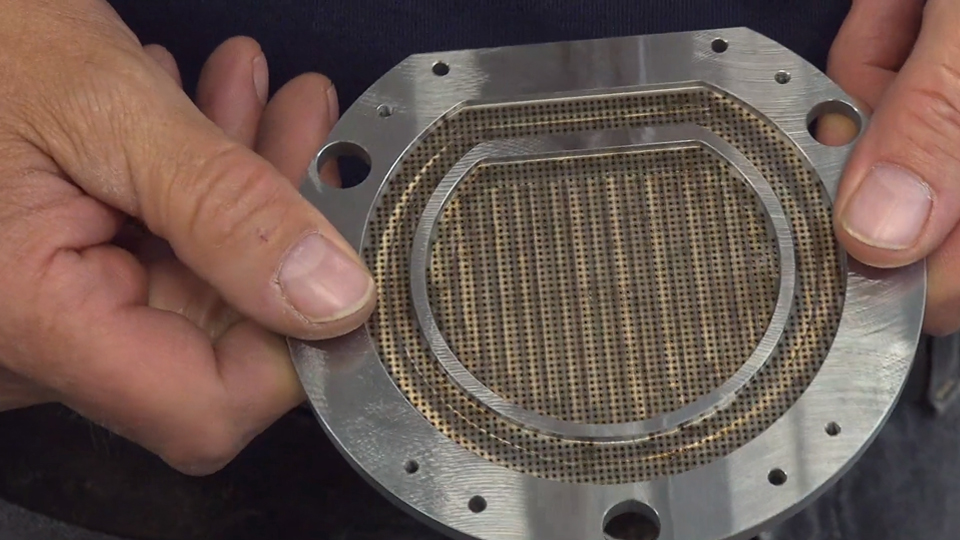

| Cutting Surface |

Telescoping Drawer with Metal Cutting Bed, Which Can Convert to Honeycomb Inserts |

| Safety | CDRH Class 1 Laser System |

| Exhaust | 250 mm (10 in) Plenum |

| Dimensions, L×W×H, mm in |

2185 × 2604 × 1848 |

| Weight, kg lbs. |

3623 |

Download LaserCube Datasheet

Technical Literature

Videos

Laser Welding Options & Accessories

In addition to the standard X-Y-Z axes and laser process head, there are several optional modules and accessories that may optimize the functionality of the system in your specific application. The most popular options are indicated below. Please contact IPG directly if you have additional requirements.

Direct Drive Rotary Stage

High-precision, high-speed rotary stage with continuous motion synchronized to X-Y-Z axes

Servo-driven rotary stage

- Brushless direct drive.

- Travel +/- 360° continuous

- Rotation speed: 600 rpm max

- Accuracy: 10 arc-sec

- Bi-directional repeatability: 4 arc-sec

- Pneumatic ER25 Collet Chuck

- Includes an additional axis of motion control

Sheet Autoloader

Fully automated sheet load/unload module for full-shift unattended operation

Flexible Sheet Size: 24 x 24 up to 48 x 48 inch

- Flexible Sheet Thickness: 0.20 up to 0.25 inch

- Sheet Stack Height up to 7” max. (# sheets x thickness): Range: 350 x 0.02” to 28 x 0.25”

- Load Time: <75 seconds (Sheet exchange)

Machine Vision

Digital video camera, illuminator assembly and integrated software to visually align and inspect parts under the control of the HMI software. Standard routines allow for automated modification of laser cutting position for compatibility with pre-punched, printed or fiducially marked workpiece.

Option includes 90 fps digital camera, controllable illumination system and integrated software

- Image field of view ~ 12 x 10 mm

- Alignment feature requirements. Any feature 1 to 3 mm in size that is unique within the 12 x 10 mm field

- Powerful HMI capabilities for generating a matrix of part positions and teaching feature recognition and fiducial positions

- Corrections include: Position offset, rotation and scaling (4-point alignment) with typically 10 µm (0.0004 inch) accuracy.

Dust Collector

- 4-cartridge downflow dust collector:

- Holds 4 cartridge filters totaling 1,016 f of filter media

- 5 HP integrated fan rated for 2,000 CFM @ 10”

- Noise attenuation enclosure

- Integrated cyclonic spark trap

- Nano-Fiber filter media with Merv 15 efficiency

- Reverse pulse filter cleaning system

- Pulse control timer board with built-in digital pressure gage

- Goyen solenoid and diaphragm valves

- Dual dust drawer collection bins

- Easy access door, with stainless steel components

- Heavy Duty 7 and 10 gage steel construction

- 5-year manufacturer’s materials and craftsmanship warranty

- All-in-one starter/disconnect/timer board/digital pressure gage (460V)

- Pre-wired to motor and solenoid valves

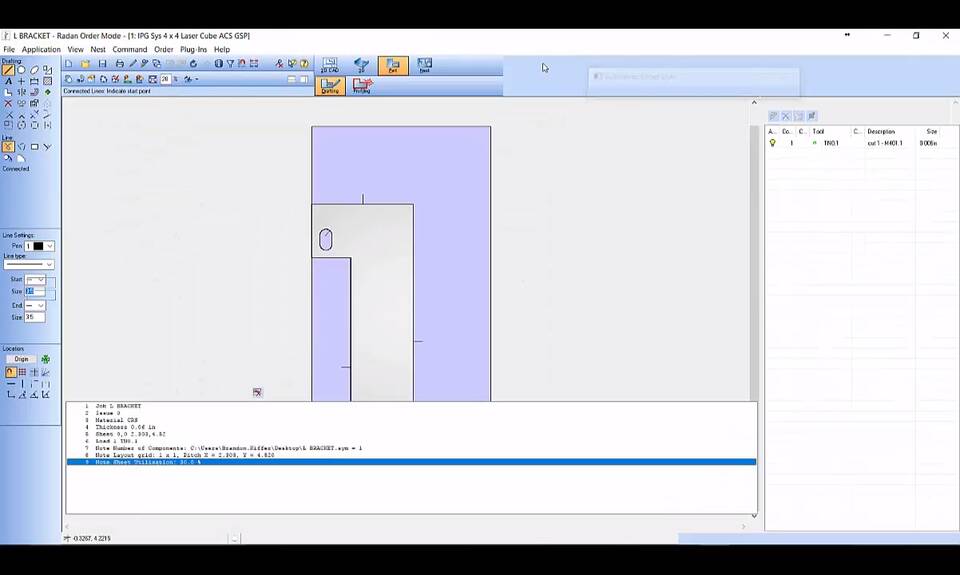

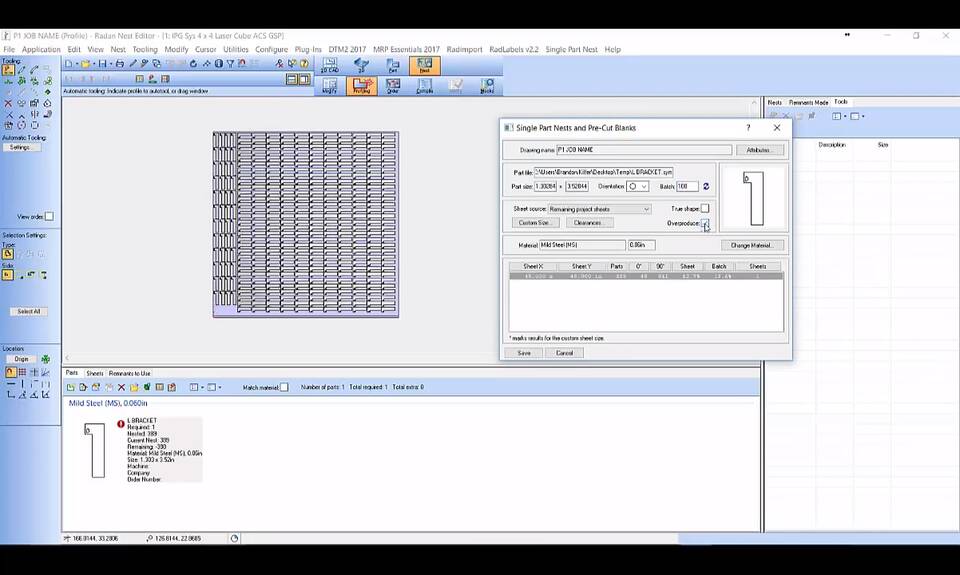

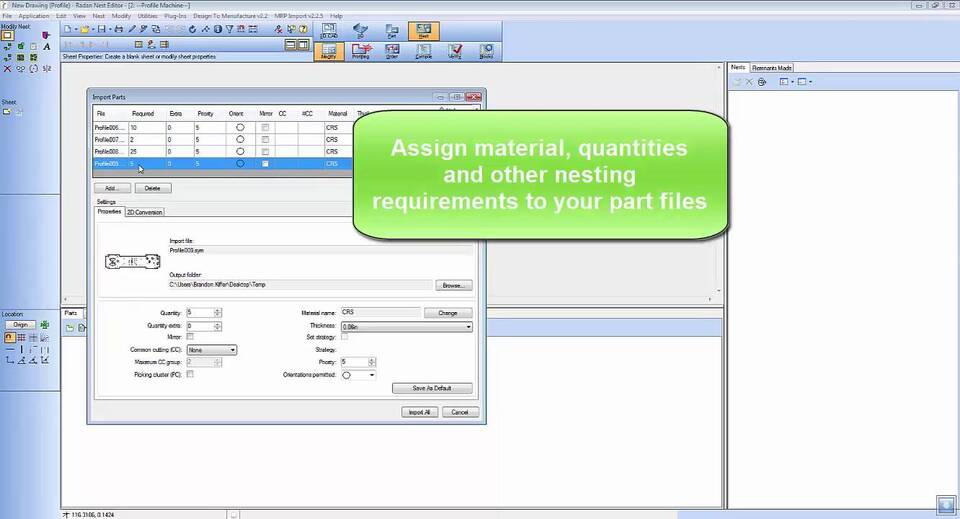

CAD/CAM Package

SigmaNEST CAD/CAM package is an optional software product used for converting CAD drawings into part programs.

- Functionality includes advanced nesting, cut sequencing, feature avoidance, and material library features to maximize the efficiency and throughput of your system.

Automatic Doors

Pneumatic actuator to automate slide door which can be controlled via HMI software or G-code.

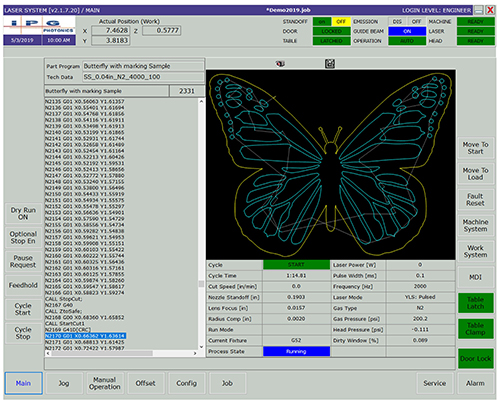

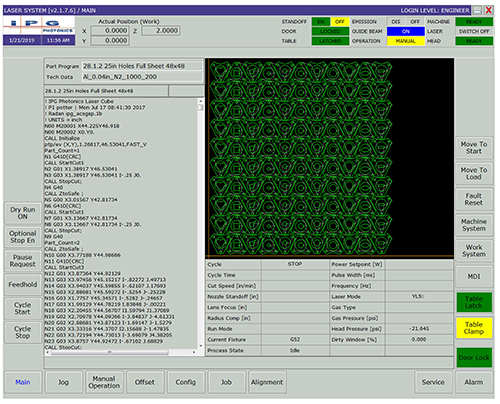

LaserCube Software

The software that runs the LaserCube flatbed laser cutting system is a customized application called HMI2 (Human Machine Interface-2) that runs as a Microsoft Windows® 10 application. It is preloaded and tested at the IPG factory and resides in the workstation’s hard drive.

Used in combination with standard G-code programming, its capabilities provide the user with a comprehensive, easy-to-use programming and operator interface.

Easy-to-Use Programming and Operator Interface

- Fully integrated control of laser, motion systems, beam, delivery, process control modules and vision functions

- Live G/M code display with production controls for interrupt and resume

- Graphical display showing cuts to be made

- Stored, editable, library of cutting parameter tables for a wide variety of materials

- Automated machine-vision based alignment and nested job setup

- On-machine part nesting for arrayed parts

- Powerful, simple to operate, vision alignment software for combo part processing

LaserCube Resource Kit

Small Parts Made Easy

Learn more about how the LaserCube flatbed laser cutting system can quickly and easily increase productivity and lower the cost per part in your facility.

Download Your Kit

How Can We Help You?