View All IPG Photonics Laser Products —VISIT CORPORATE WEBSITE✕

LightWELD

Revolutionizing the Welding Industry

Handheld Laser Welding and Cleaning Systems

Easy to Learn & Operate • Simple & Fast to Set Up • Consistent High-Quality Results

LightWELD Unbeatable Benefits

- FAST: Up to 4X faster than TIG

- VERSATILE: Wide range of materials – up to 1/4 in. (6.35 mm)

- EASY: Optimized presets reduce learning curve

- CONSISTENT: High-quality, repeatable results

- FLEXIBLE: Simple and challenging applications

- PRODUCTIVE: Pre- and post-weld cleaning capability

Learn More - Download LightWELD Brochure

Laser Welding Automation Made Easy

Looking to introduce automation into your shop but want to skip the expensive and complex integration?

The LightWELD Cobot System combines LightWELD technology with a collaborative robotic welding system to make automation easy — no programming experience required.

LightWELD - Turnkey Handheld Laser Welding & Cleaning Systems

- Adjustable laser welding power up to 1500 W

- Preset & user-defined modes optimize material-thickness combinations

- Wobble welding controls for 5 mm of additional weld width

- Rear panel provides intuitive connections for power, process gas and external accessory controls

- Cleaning power up to 2500 W peak for greater welding quality and finishing capability

EXPERIENCE LightWELD YOURSELF!

- Fast and Easy Setup

- Built-In Presets for Optimized Welds

- Welding Steel, Aluminum, Copper, Titanium, Nickel Alloys

- Cleaning Pre- and Post-Weld

- Live Q&A

Watch Paul Sableski from Weld.com demonstrate the features, capabilities and just how easy LightWELD XC is to set up and operate at “lightning speed.”

Paul uses LightWELD XC to quickly create::

- 3 mm Aluminum Butt Weld

- Stainless Steel T-Joint, 6 mm to 1 mm

- Stainless Steel Lap Joint with wire feeder

LightWELD - Less Heat & Distortion for More Productivity & Flexibility

| Traditional Welding Methods | LightWELD Laser Welding & Cleaning | |

|

Speed |

Average | Up to 4X Faster than TIG |

| Quality | Depends on user experience | Consistent high-quality results |

| Learning Curve | Steep | Quick and easy |

| Material Flexibility | Limited with consumables changes | Wide range with no set up |

| Distortion & Deformation | High | Very Low |

| Heat Affected Zone | Large | Small |

| Wobble Welding | No | Yes - up to 5 mm additional weld width |

| Pre- and Post Weld Cleaning | No | Yes - up to 15 mm cleaning path |

TIG welding is a time-consuming, two-handed welding method that requires an experienced, highly-skilled operator. TIG welding may generate extreme heat that deforms thin materials, produces poor visual finishes, is difficult when welding copper, and limited when welding metals of dissimilar thicknesses.

MIG welding requires consumable wire, material pre-cleaning and beveled joints for thick metals for full penetration. Travel and work angles are limited and vertical positions are extremely challenging.

“In my 41 years in the business, I have never seen a welder that allows beginners to make welds like seasoned pros!”

LightWELD - Factory Presets Ensure Optimized Welds & Cleaning

- Simple preset selection ensures consistent high-quality laser welds and cleaning

- Presets include wobble welding function to accommodate wider seams and for parts with poor fit-up

- Operators can instantly switch between presets to process multiple material-thickness combinations

- Advanced operators can customize presets, save for future use and can be used by novice operators to produce the same results

- Novice operators require less training which reduces labor costs while preserving quality, increasing productivity and decreasing scrap

LightWELD is Fast & Easy to Set Up

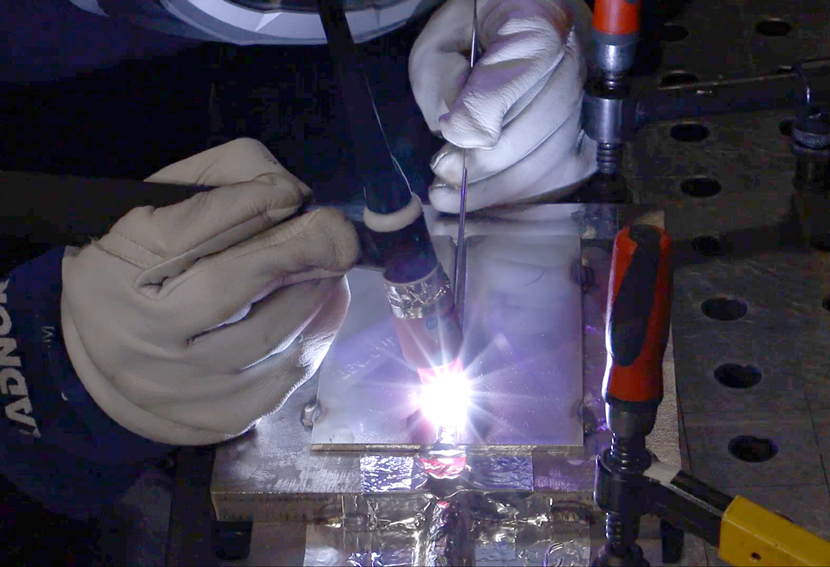

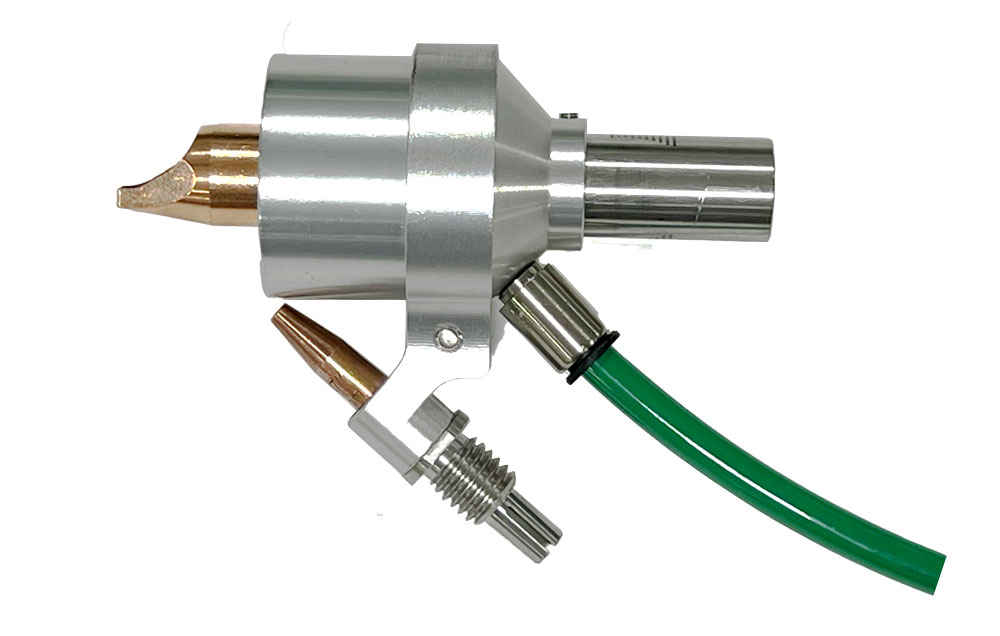

- Ergonomic, compact and proven to be the most comfortable and easy to use laser gun with built-in wobble welding functionality.

- 2-step trigger and part contact sensor enhance operator safety

- Purpose-built nozzle tips for various weld joint types and pre and post weld cleaning applications

- Quickly switch from standard laser welding to wire welding, and from laser welding to laser cleaning

- A single cable from the unit delivers laser power, gas and control connections to the gun

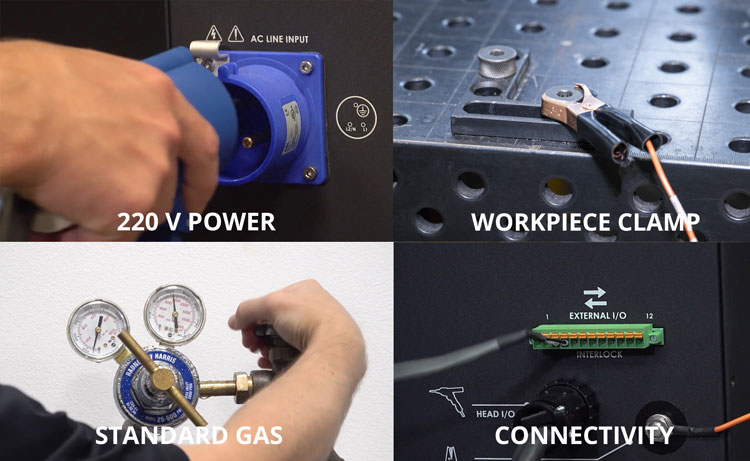

Fast and Easy Setup

- Clearly labeled rear connections make getting started fast and easy

- Simply plug in power cord and gas connection, attach clamp to work surface, and the system is ready to go.

- Laser power, gas, and gun control are delivered through a single cable.

- An ethernet computer connection provides access to advanced parameter settings to fine tune and save process parameters.

Get Social with #LightWELD

LightWELD Operator Safety Features

- Key switch control to secure system from unauthorized operation

- Emergency-stop button for immediate shut down

- Safety interlock verifies integrity of laser delivery to the welding gun

- 2-step weld gun trigger, enable and then fire, for intentional operation

- Part contact electrical interlock turns off the laser power if the welding head is not in contact with the welded parts

- Door switch interlock circuits shut down laser if anyone other than operator unexpectedly enters the welding area

LightWELD is a Class IV laser system and safety precautions are required. Operator protective equipment including welding gloves, welding shield and 1070 nm laser-safe glasses are required.

Get Your Shop Laser Welding Ready

IPG offers a complete assortment of products, accessories and services to successfully implement LightWELD laser welding in your operations. Our offering can deliver quick set-up, improved safety, faster technology onboarding and an overall better value.

Contact us about more information regarding laser welding premium offerings by calling us at 1.508.373.1100 x3.

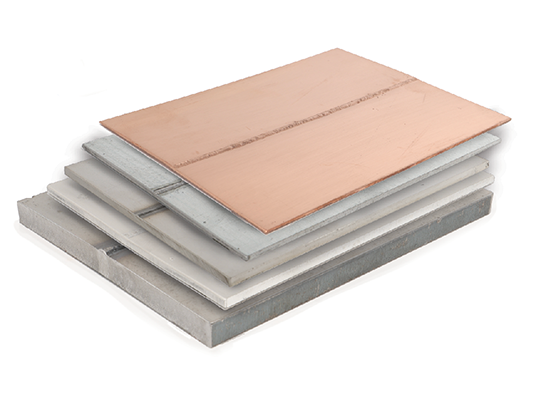

LightWELD Material & Thickness Welding Range

Thick, thin, reflective and dissimilar metal welding without wire that

is difficult or impossible with traditional methods, plus weld materials with different electrical conductivity

- High-speed welding across a wide range of materials and thicknesses

- Low heat input for minimal part distortion or deformation

- Built-in factory presets for all materials and thicknesses

Material |

LightWELD XR |

LightWELD 1500

|

|---|---|---|

Material |

LightWELD XR |

LightWELD 1500

|

|

Stainless Steel |

up to 6.35 mm |

up to 4 mm |

|

Galvanized Steel |

up to 6.35 mm |

up to 4 mm |

|

Mild Steel |

up to 6.35 mm |

up to 4 mm |

|

Aluminum |

up to 6.35 mm |

up to 4 mm |

|

Aluminum |

up to 5 mm |

— |

|

Nickel Alloys |

up to 5 mm |

— |

|

Titanium |

up to 5 mm |

— |

|

Copper |

up to 2 mm |

— |

LightWELD Pre-Weld Cleaning

LightWELD XC and LightWELD XR provide pre-weld cleaning for stronger, higher-quality welds

- Any contaminants can enter the weld pool and compromise weld integrity

- Pulsed cleaning power up to 2500 W peak power evaporates undesired surface elements

- Fast and effective removal of contaminants such as oxides, rust, paint, oil, or grease from surface without the use of chemicals or abrasives

- Up to 15 mm of adjustable cleaning width with one pass

LightWELD Post-Weld Cleaning

LightWELD XC and LightWELD XR provide post-weld cleaning improves visual finishes

- Post-weld cleaning removes soot, debris, or any sign of localized heating

- Dramatically reduces time, cost and scrap

- Create visually appealing welds while eliminating need for post-grinding

- Up to 15 mm of adjustable cleaning width in one pass

LightWELD offers Welding & Cleaning in a Single System

LightWELD XC and LightWELD XR can switch from welding to cleaning in just seconds

- Specially designed welding and cleaning nozzle tips for any joint configuration

- Increased productivity using single system for multiple fabrication processes

- Simply loosen the collet and insert a welding or cleaning nozzle, select the appropriate mode and the system is ready to clean or weld

"The travel speed and diversity of materials

that can be welded is unbelievable"

Built-in Wobble Welding for Increased Productivity

- Simple on-the-fly control of up to 5 mm of additional weld width with selectable frequencies

-

Creates highly aesthetic seams and welding of parts with poor fit-up

- Wobble parameters are preprogrammed and can be saved by the operator and recalled immediately as needed

- In cleaning mode, the wobble function provides adjustable cleaning scan widths up to 15 mm

Optional Wire Feeding Package

- Wire welding capability extends laser welding applications to poorly fit-up parts

- Used for low carbon steel, stainless steel, aluminum and non-ferrous metals and alloys

- Wire feed speed range 40 – 600 cm/min (15 - 230 ipm)

- Wire diameter capacity 0.8 to 1.6 mm ( 0.035''- 0.063'')

- Wire feed tips: 0.8mm, 0.9mm, 1.2mm, 1.6mm

- 2x V-rollers and steel liners for hard wire , 2x U-rollers and Teflon liners for soft wire

- Package includes wire feed unit, electrical connections, nozzle assembly and IPG Process Mode software

LightWELD Laser Welding & Cleaning Systems

Easy to Learn

Built-in factory presets for welding and cleaning reduce learning curves, new welders can be trained within hour and experienced welders realize an immediate increase to productivity

Highly Productive

High-speed welding that is 4X faster than TIG, with simple material preparation and minimal post-finishing, plus wobble welding and wire feed options for consistent high-quality results

Highly Capable

Easily weld and clean thick, thin and reflective metals with low heat input from < .040" (1.0mm) up to 1/4" (6.35mm) with minimal part distortion, improved visual appearance and increased overall part quality

New LJ-WF002 Laser Welding Wire Feeder

Provides significant improvements over previous model: high-accuracy, robust feeding mechanism enhances LightWELD user confidence and tactile feedback while welding with both hard AND soft wire!

- Wire Feed Delivery Length:

- Steels and other hard wires: 10 ft.

- Aluminum and other soft wires: 10 ft.

- Wire Feed Speed Range: 0.5 – 230 ipm

- Compatible Wire Diameters: 0.030” – 0.063”

- Wire Reel Capacity: Up to 30 lbs. (12” diameter)

- Compatible Wire Materials: Steel, Stainless Steel, Aluminum, Copper, Nickel

- Power Requirements: 115 – 230 V 50/60 Hz

- Weight and Dimensions: 30 lbs. I 20.5 in. L x 9.7 in. W x 16.5 in. H

- User Controls: Feed Speed, Feed Delay, Retract Speed, Retract Time, Manual Jog, Jog Speed

Buy Now

LightWELD Carbon Fiber Laser Welding Helmet

The LightWELD Carbon Fiber Welding Helmet is a lightweight welding helmet designed to provide unsurpassed operator protection. No ordinary carbon fiber, the unique properties of the LightWELD carbon fiber helmet and lens system produces a weld helmet that is designed to be compliant with EN207 directive and offers impact protection to ANSI Z87+W16 rating.

Features

- Superior Protection - Designed to meet EN207 DLB8 + ILB9 @ 1070nm and ANSI Z87+W16 rated

- Carbon fiber shell – Ultra lightweight construction

- Optical filters provide IR and UV protection, plus fixed welding shades for user comfort

Benefits

- Enhances worker safety – impact and laser protection in one weld helmet

- Lightweight construction reduces neck fatigue and boosts productivity

- Protects user from laser and emitted radiation

Buy Now

Gas Lens Nozzle

The precision gas lens nozzle is ideal solution for welders seeking to improve gas shielding performance when welding materials sensitive to oxygen, moisture, or other vapors or gases that may be present in the atmosphere. The improved purging reduces formation of undesirable compounds in the weld that may lead to excessive oxidation or structural defects.

Features

- Precision Machined Diffusers

- Wire Feed Compatible

- Easy Installation

Benefits

- Superior weld pool shielding

- Reduced HAZ

- Improved weld quality

Buy Now

Dual Wire Feed Adapter

Dual Wire Feed Adapter allows simultaneous feeding of two wires into the weld pool. LightWELD's wobble features allows for simultaneous welding of both wires and the base material. Where weld certifications require larger fillet widths or radius, the dual wire feed adapter efficiently adds material without the need to make multiple weld passes, maintaining worker productivity and reducing overall heat input into the workpiece.

Features

- Dual Wire Feed Adapter

- Wire diameter up to 0.063"

- Twin Groove Weld Tip

Benefits

- Increase fillet dimensions

- Increase tolerance for poor part fit up

- Faster material build up

Note: requires two wire feeders or compatible dual wire feed unit.

Buy Now

|

|

LightWELDHandheld Laser Welding |

LightWELD XCHandheld Laser Welding & Cleaning |

LightWELD XRExtended Range Handheld Laser Welding & Cleaning |

|

Laser Type (Welding mode) |

Air-Cooled Ytterbium Continuous Wave 1070 nm Fiber Laser1 |

||

|

Laser Output |

1500 W Average Power, with 2500 W Peak Power Class 1 Red Guide Beam |

||

|

Laser Output |

— |

2500 W Peak Power |

|

|

Umbilical Cable |

Utilities Bundle from Base Unit to Head including: Fiber Laser Delivery, Process Gas, Process Head Control Signals and Safety Interlock Circuits - Length: 10 m (~32 ft) |

||

|

Cooling |

Air Cooled – No External Chiller Required |

||

|

Weld Head |

Handheld Wobble Welding Head Collimating Length 40 mm, Focus Length 120; Spot size 150 μm Incorporating Safety Control Sensors and Laser-on Indicator User-changeable nozzles for planar, internal corner, and external corner welds |

Handheld Wobble Welding Head Collimating Length 50 mm, Focus Length 120; Spot size 60 μm Incorporating Safety Control Sensors and Laser-on Indicator User-changeable nozzles for planar, internal corner, and external corner welds

|

|

|

Weld Head Cleaning Nozzles |

— |

Set of three nozzles for wide-angle scanning |

|

|

Spot Size |

150 μm |

60 μm |

|

|

Wobble Length |

Adjustable up to 5 mm |

||

|

Cleaning Scan Length |

— |

Adjustable up to 15 mm |

|

|

Process Gas |

Argon, Nitrogen, Argon + CO2 mix |

||

|

User Interface |

Front Panel Controls of Laser Power, Mode, Wobble Length and Wobble Frequency: (Rotary knobs with digital display). Laser On/Off key Switch, E-Stop Button. - Status Indicator Lights |

||

|

Computer Connection |

Ethernet Connection to Web Page Interface Allowing Viewing/Adjustment of Process Mode Settings and System Status and Alarm Signal |

||

|

Safety |

Class 4 Laser Device. Customer responsible for standard ANSI Z136.1 safety precautions. System features include key for laser ON/Off, 2-step laser operation trigger (Enable and Fire), Part-head contact safety circuit, Facility door interlock circuit |

||

|

Operating Environment |

Storage temperature -20 to 60 °C. Operating range +5 to 35 °C |

||

|

Ease of Aluminum Weld |

Moderate |

Easy |

|

|

Single-Side, Single Pass Material Weld Capability |

Stainless steel, mild steel, galvanized steel, aluminum up to 4 mm |

Stainless steel, mild steel, galvanized steel, aluminum up to 6.35 mm, copper up to 2 mm |

|

|

Facilities Requirements |

Electrical: 220 V, 1 Ph, 50/60 Hz, < 30 Amp |

||

|

Weld Base Unit (W x D x H) |

316 x 641 x 534 mm (12.4 x 25.2 x 21 in) |

||

|

Weld Module Weight |

53 kg, (118 lbs) |

||

|

Accessories |

Safety Glasses, Power Connecting Plug, Ethernet Cable |

||

1. Laser made in USA

LightWELD Support and Service

Contact our dedicated LightWELD support team by phone, email or the form on this page to:

- Answer your questions

- Request service

- Order spare parts

Phone: +1 508.506.2877

Email: LightWELD@IPGPhotonics.com

Made In USA – Supported Globally

The heart of the system, the LightWELD laser is manufactured at IPG’s state of the art production facilities located in Oxford MA, USA. Final assembly, testing and calibration is performed in Marlborough, MA, USA. If service is ever needed, IPG repair facilities are distributed regionally for rapid response.

Service Locations:

- Marlborough, MA

- Novi, MI

- San Jose, CA

Visit the LightWELD online support site to access:

- User Manuals

- Welding Mode Charts

- Support Videos

- Spare Parts Portal

LightWELD Sales

Contact Sales:

Contact support

With the LIGHTWELD COBOT Fabrication Toolkit, which integrates low-cost commercial collaborative robots for repetitive welding tasks, the LightWELD system can be used in either manual or automated manufacturing modes to improve productivity. Through intuitive and easy to use drag and drop programing combined with manually guided waypoint programming, COBOT integration is an ideal solution for lower volume, high product mix applications.

Productivity can be increased, as LightWELD offers the convenience of being easily converted between manual and COBOT operation, particularly for more complex projects not practical for the latter. Additionally, it is programmed with ease for new projects and features fast change over for existing ones. To reduce costs and optimize workforce for better utilization, employees can be upskilled to undertake more productive tasks and critical projects. The use of LightWELD also leads to improved product quality and consistency by eliminating rework and scrap due to COBOT control of laser settings. Furthermore, the robot runs at programmed speeds, ensuring a more uniform weld.

An experienced integrator will be able to provide advice on which applications are well suited for COBOT integration and which require more advanced laser and robotic technology, such as high-volume production applications.

The COBOT integration toolkit provides the following features:

COBOT Command Software Interface

- Manufacturer-specific application installs on robot controller.

- Allows COBOT to select LightWELD process parameters.

Mounting Cradle

- Tool-less mounting systems allow for easy switch between manual and COBOT welding.

- Two illuminated smart buttons enable free-drive mode and programming of waypoints.

- Robot tool center point training tip insert.

COBOT Cable Management System

Remote Interface Box

- Allows COBOT controller to remotely control laser emission.

- Provides feedback to robot when LightWELD is in “COBOT control” mode.

Documentation

Benefits

The LightWELD COBOT Fabrication Toolkit provides several benefits that make it and ideal complement for LightWELD systems.

Practicality

Easy removal of LightWELD for hand held laser welding when COBOT use is not practical.

Better Weld Quality

The angle of the weld tip is precisely controlled for optimum weld melt pool formation, resulting in a superior weld.

Increased Flexibility

Automatic selection of laser parameters increases flexibility and utilization of the LightWELD unit. COBOT capability to control weld parameters enables separate process recipe for the spot weld compared to the seam weld. No need for the operator to change parameters.

Scrap Reduction

Elimination of human inconsistency ensures better production yield. For thinner materials, risk of burn through may be eliminated. The COBOT starts and stops at the same position every time, reducing rework.

Better Part to Part Consistency

The highly repeatable motion profile and capability to set the contact force of the COBOT ensures that the tip stays right on the centerline of the joint during welding.

Immediate Productivity

COBOTs are quick and easy to setup.

Frequently Asked Questions

What are good applications for COBOT integration?

Low volume high product mix applications that can be welded by hand.

What are the fixturing requirements?

Repeatable fixturing and part fit up are required to hold the workpiece in correct location for welding.

What COBOTs are supported?

Fanuc and Universal Robots are currently supported.

Does IPG provide COBOT integration services?

No, IPG does not provide COBOT integration services. Integration of the COBOT is solely the responsibility of the system integrator.

How are robot positions programmed?

A smart button interface enables programing COBOT positions using free drive mode.

Can I use multiple weld parameters on a project?

Your welder will be interfaced with the COBOT control unit, this allows the COBOT to trigger the laser and set weld parameters.

Does COBOT replace traditional robotic welding technology?

No, it does not. Traditional robotic welding systems often feature process and equipment monitoring technology and operate at higher speeds and precision. An experienced integrator will be able to provide guidance on applications suitable for COBOTs.

LightWELD Frequently Asked Questions (FAQ)

Is LightWELD really faster than MIG and TIG welding?

Yes, LightWELD travel speed is up to four times faster than traditional methods, fixturing is simpler or not necessary, and post-weld grinding or sanding is not needed or significantly reduced – all of which increases productivity while minimizing rework.

Is LightWELD really that easy to learn?

Yes, compared with MIG and TIG welding, either of which can take a lifetime to master, LightWELD is quick to learn, allowing new users to make high-quality welds in just a few hours.

The controls look confusing. How do I know what to adjust?

LightWELD comes preloaded with optimized welding parameters for the most common materials and thicknesses. You can adjust the power up or down to match your travel speed and desired penetration, and you can save those settings and recall them as needed.

Can LightWELD weld dissimilar metals or parts with different thicknesses?

Yes, you can easily weld dissimilar metals like copper to stainless steel or to aluminum, plus parts with different thicknesses across all weld joint types: tee, butt, corner, lap and edge.

What is the maximum material thickness that can be welded?

For stainless steel, galvanized steel, mild steel and aluminum, you can weld single-sided up to 4 mm and double-sided up to 10 mm – copper single-sided up to 1 mm and double-sided up to 2 mm.

What about vertical welding or upside down welding?

LightWELD excels at both vertical and upside down welding since there are normally no consumables and minimal spatter produced, making it safe and easy to weld in any position.

Is the laser beam constant or can it be pulsed?

LightWELD offers five modes of operation to match your needs:

- Continuous wave - the laser is on constantly for maximum penetration and travel speed

- Pulsed mode – laser pulses producing less energy for slower welding with less heat input

- Tack mode – to create identical tack welds

- Stitch mode – used for repeated tacking or overlap welds

- High peak power mode – short bursts of high power used to penetrate reflective metals

What is the duty cycle?

You can run LightWELD at 100% duty cycle at the maximum 1500 watts of laser power.

What’s wobble welding?

Wobble welding oscillates the beam back-and-forth at various frequencies to produces wider seams and more aesthetic welds. It is also helpful for parts with poor fit-up. LightWELD comes with optimized, preprogrammed wobble parameters and allows on-the-fly control of up to 5 mm of wobble welding at adjustable frequencies up to 300 Hz.

Where is LightWELD manufactured?

The heart of the system is the laser source, proudly Made in the USA at our production facility in Oxford MA, USA. Final system assembly, testing and calibration is performed at our Marlborough MA, USA facility using additional components sourced through approved suppliers where we seek ISO 9000-2015 certification and who provide effective support, adhere to the highest ethical standards and have a proven record of law-abiding conduct.

Is there a datasheet?

Yes, you can download the LightWELD 1500 datasheet here.

Where can I see a demonstration of LightWELD?

You can sign up to register for a live demo here.

How do I buy LightWELD?

Click here to fill out a contact form and a LightWELD specialist will get back to you asap. If you would like to speak with someone now, please call (508) 506.2877

Are You Ready to be Amazed?