View All IPG Photonics Laser Products —VISIT CORPORATE WEBSITE✕

E-Mobility Manufacturing Solutions

Partnering with manufacturers and their automation integrators to increase quality, improve production processes and lower overall production costs

IPG Laser Technologies Enable E-Mobility Growth

Manufacturers of battery cells and modules, electric vehicles and energy storage systems come to IPG for flexible, reliable and productive laser-based manufacturing solutions. Covering the range of battery production steps from processing of electrode films, welding cells to busbars or the structural components of the battery trays, our technical leadership in the area of laser-material interactions allows us to provide industry-leading guidance and support to automotive manufacturers and their chosen production line integrators.

Whether it is the unmatched power levels of the pulsed foil cutting lasers, the unique capabilities of the adjustable mode beam lasers for spatter-free welding of copper and aluminum, or the patented real-time weld measurement technology; IPG is continually working to optimize laser materials processing capabilities to keep you ahead of rapidly evolving E-Mobility trends.

Speak to our E-Mobility Team

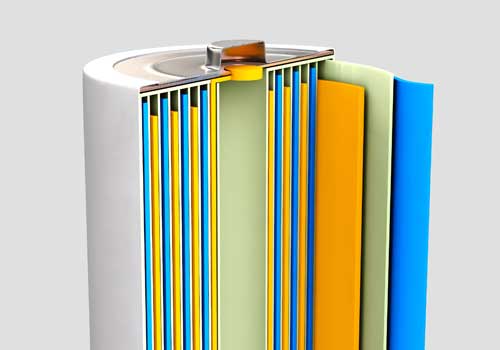

Li-ion Cell Manufacturing

Laser processing in Li-ion cell manufacturing starts with the electrode films, with laser cutting and notching of the foils, drying the dielectric coatings, and pre-weld cleaning of the contacts. Lasers are essential in cell assembly, with processes for welding electrodes to terminals, injection hole sealing and can-caps welding.

Solutions include high-power pulsed lasers lasers for cutting and single-mode dual-beam (AMB) lasers for high-speed, low heat metal welding.

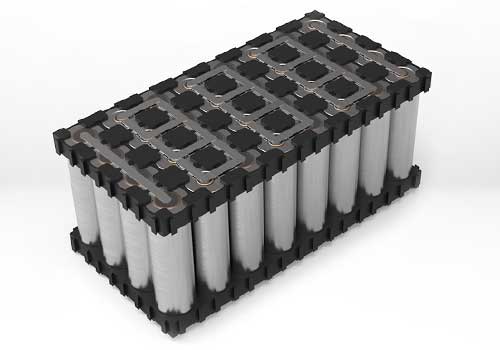

Busbar Welding

Assembly of cells into modules using high-conductivity busbars or lattices relies on rugged, reliable, low resistance electrical contacts.

For prismatic, pouch and cylindrical cell modules, laser welding provides better electrical performance, and is significantly faster compared to alternate technologies. For cylindrical cell batteries with thousands of connections, higher busbar welding higher speed equates to significant production cost savings.

Solutions include dual-beam AMB lasers for welding, with optional patented LDD real-time weld measurement for 100% inspection of the weld quality.

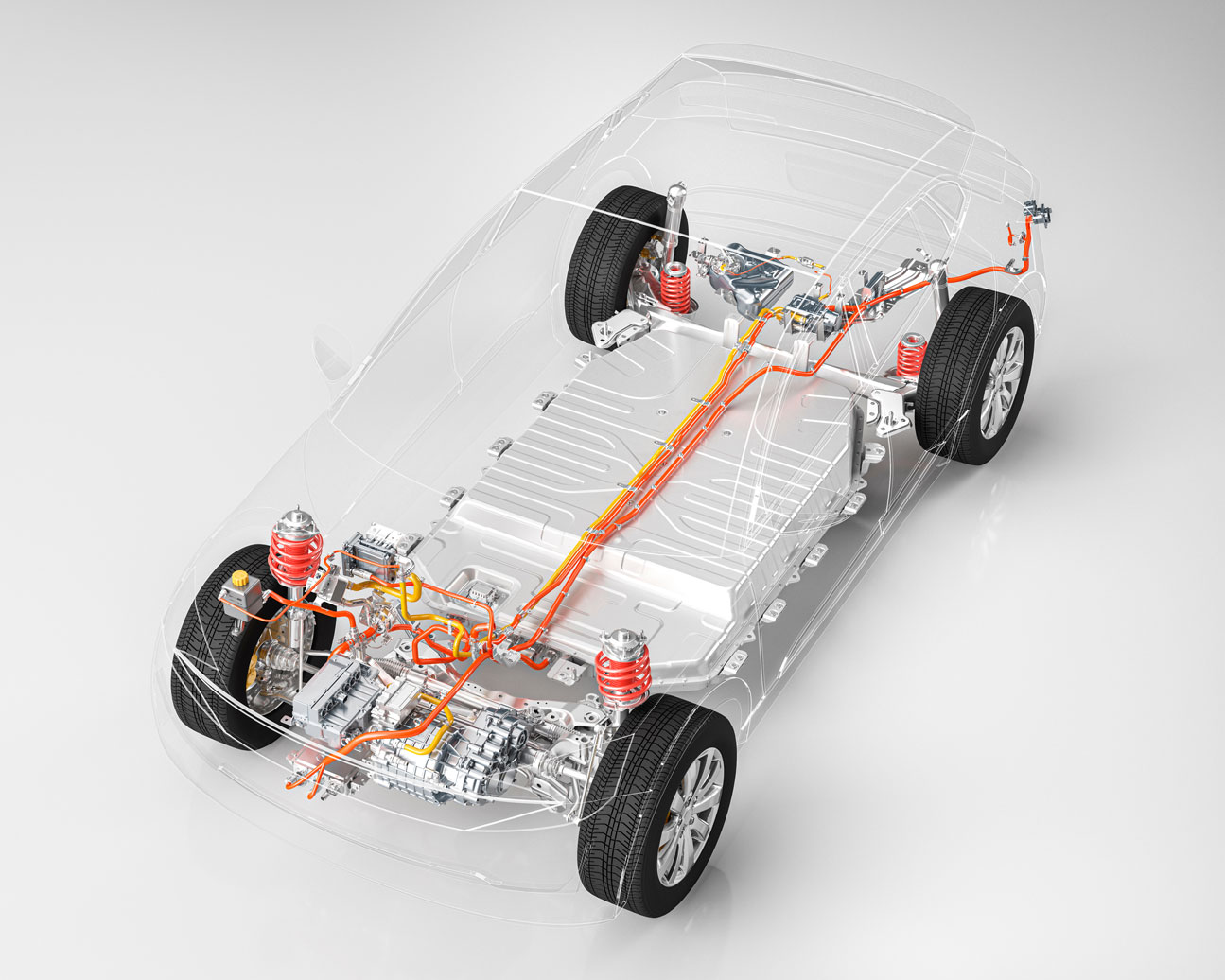

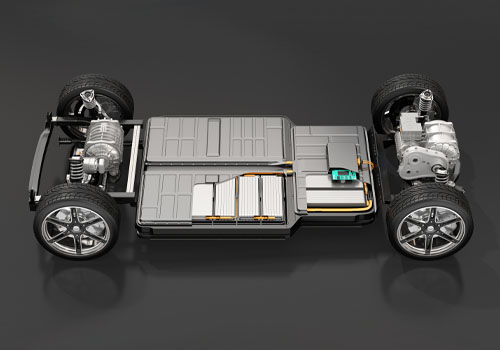

Battery Packs

Building modules and battery packs generally involves two different types of processes. First, making electrical connections to increasingly thick conductors, frequently of dissimilar or coated materials. Second, closing the robust mechanical cases that enclose the electrical elements.

For many designs, the enclosed battery pack functions as a structural element in the vehicle, making high integrity, high strength welds a mandatory requirement.

Solutions include AMB lasers for low-porosity welding of copper connections and aluminum cases, high-power lasers and scanning heads for high-speed, on-the-fly case welding, and LDD real-time weld measurement and verification.

Electric Motors

In addition to standard mechanical fabrication of motor body casings, E-Mobility has seen a rise in requirements for stripping insulation, and then welding, the hairpin conductors.

Solutions for insulation stripping are generally pulsed lasers combined with scanners that are integrated into the motor assembly tools. For hairpin welding, laser and scanners can be purchased individually, or as a combined Integrated Laser Welding System (ILWS) module, which includes a programmed controller and vision alignment system to make tooling and line integration even easier.

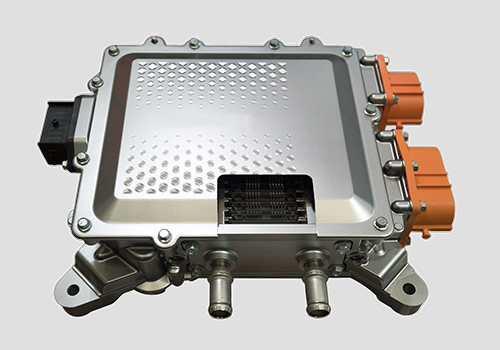

Electric Components & Modules

Battery control units and inverters typically require making electrical connections to dissimilar or coated metals, and case enclosures.

In addition to low electrical resistance joints, minimizing spatter during the welding process is important as the ejection of molten material from the weld pool causes weld porosity and creates electrically conductive debris potentially causing electrical defects.

AMB dual-beam lasers utilize the high power density of the single-mode core beam to initiate the weld and the enlarged ring beam to stabilize the weld pool, enabling reliable, high-speed processing.

On-Demand Battery Welding Webinar

The example cases discussed will include:

- Solving spatter issues and increasing the process window in high-speed welding of copper, aluminum, busbars and connectors

- Using air-cooled laser in manufacturing steps where water is not allowed

- Reducing cycle time using an integrated laser welding solution comprising laser, beam delivery with scanner and dedicated controller.

Laser Sources and Products for E-Mobility Integration

E-Mobility solutions start from off the shelf laser and beam delivery products, and can include process development, integration support, integrated system programming, and turnkey laser processing modules and systems.

Find out how these can benefit your E-Mobility initiatives.

Turnkey Laser Processing Systems for E-Mobility Production

We offer a wide range of turnkey laser processing solutions for E-Mobility manufacturing applications. These systems are used in applications from process development and prototype part production through fully automated production.

These systems can typically accelerate the time to first deploy a laser manufacturing step as we provide the laser process development, component integration and software programming.

How can we help you?

As the leader in industrial laser materials processing, IPG has provided tens of many thousands of custom laser solutions installed around the world, and we understand that every job is unique in its own way.

Talk through your ideas with our laser processing specialists, or better still visit us in one of the 27 applications facilities where you can meet the engineers and experience laser processing first-hand.