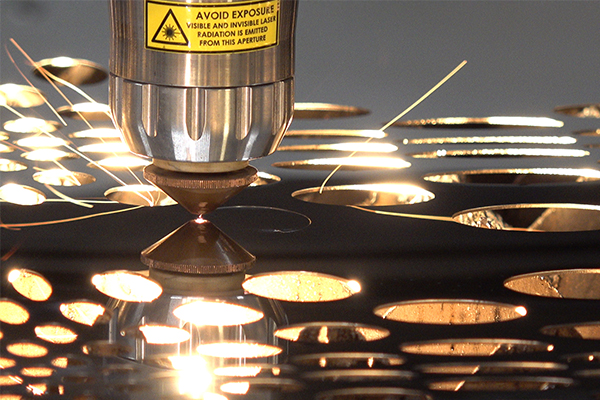

Fiber Laser Cutting Machine

Save Time, Money and Space on Your Shop Floor

Fiber lasers are changing how the world does business by lowering the cost of doing business. Manufacturers can now precision cut hundreds of small parts in less than an hour with LaserCube flatbed laser cutting systems.

From prototyping to production, LaserCube flatbed laser cutting systems maximize your output and minimize operating costs. To learn more about LaserCube flatbed laser cutting systems, download your resource kit.

Your LaserCube Flatbed Laser Cutting System Resource Kit Includes:

- Systems Specifications and Facility Requirements

- Application Videos

- LaserCube Customer Case Studies