View All IPG Photonics Laser Products —VISIT CORPORATE WEBSITE✕

Applications

Laser Cleaning

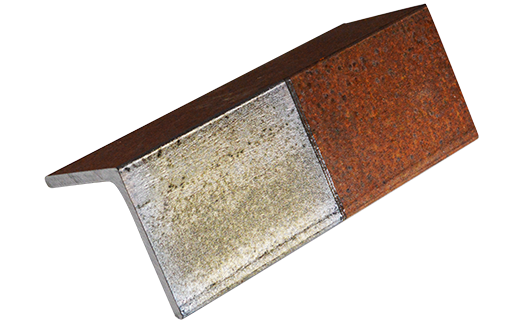

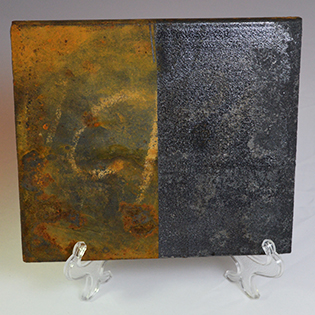

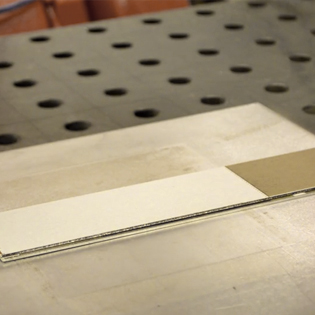

Lasers can provide high-speed cleaning and surface preparation in virtually all industries. The low-maintenance, easily automated process can be used to remove oil and grease, strip paint or coatings, or modify surface texture, for example adding roughness to increase adhesion.

- No abrasive materials are used, with no problems of contaminant separation and disposal

- No solvents are used - chemical-free and environmentally friendly process

- Spatially selective – cleaning only the area required, saving time and costs by ignoring regions that don’t matter

- Non-contact process never degrades in quality

- Easily automated process that can lower operating costs by eliminating labor while giving greater consistency in results

Improve your cleaning productivity - contact a local IPG laser cleaning engineer to learn how.

Why are more manufacturers using laser cleaning for material preparation?

Laser cleaning offers multiple advantages over traditional approaches. It does not involve solvents and there is no abrasive material to be handled and disposed of. Compared with other processes that are less detailed, and frequently manual processes, laser cleaning is controllable and can be applied only to specific areas of a part, can be easily automated to maximize productivity, and provides the guaranteed repeatability demanded by an increasing number of quality standards.

Abrasive Blasting vs

Fiber Laser Cleaning

While the cleaning is easy and effective, cost lies in the collection and disposal of the blast media, which often has to be separated from the paint debris, which has its own treatment issues.

Fiber lasers eliminate the blast media problem. They provide a more controlled process that does not accidentally damage a surface through excessive removal, and can also be used on thin and composite materials that would be damaged by the particle impact. Fiber laser cleaning is always consistent, independent of operator effects, and can scale to suit the job size by selection of the laser power.

Cold Jetting vs

Fiber Laser Cleaning

Also known as dry ice blasting, cold jetting has similar characteristics to abrasive blasting, but without the problems of abrasive material recovery and disposal.

Fiber laser cleaning has little risk of operator hearing damage, has no special ventilation requirements, and is more easily controlled when dealing with small parts.

Chemical Cleaning vs Fiber Laser Cleaning

Good for cleaning surface contamination from a whole part, chemical cleaning is not easily applied to a selective area. Disposing of the chemicals is an increasingly difficult and costly challenge due to regulatory controls.

Fiber lasers can be applied selectively. With no chemicals to degrade, quality is consistent, and there are no chemical solvent disposal issues. With no drying time, parts are available immediately.

Thermal Cleaning vs

Fiber Laser Cleaning

Thermal cleaning is often used for removing organic contaminants such as polymers and plastics, often with excessive heat necessary for the application.

Laser cleaning is dramatically faster. It can remove a wider range of materials, including metals and the temperature of the part remains lower, with less chance of cracking or distortion. Laser cleaning is more energy efficient, and parts are immediately available.

Advantages of IPG Fiber Laser Cleaning Technology

Elimination of Chemical Solvents

Handling and disposal of hazardous chemical solvents is eliminated by laser cleaning. The reduction in costs of consumable solvents and the expensive requirements for post process treatment and disposal of these chemicals are not a factor for laser cleaning, making it both the environmentally preferred and lowest cost solution.

Controllable Non-Damaging Process

Laser cleaning provides greater levels of control than are available for any competing process. The highly focusable and steerable laser beam can be directed precisely as desired, while sensitive and repeatable power settings deliver only the amount of energy that is called for. The range of IPG fiber lasers includes pulsed models specifically designed to produce optimum cleaning results with a minimum of heat generation.

High Precision Flexibility

Laser cleaning is a uniquely flexible and precise process that is used in the surface preparation of metals, composites, and glass across a variety of applications and industries. No other ablation method is capable of highly-selective material removal with micron-level control across parts of all shapes and sizes.

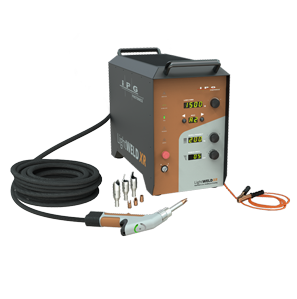

Laser Cleaning Systems

Get an Application Evaluation

Discover how IPG's laser technology can help solve your shop's biggest challenges.

Schedule Evaluation