View All IPG Photonics Laser Products —VISIT CORPORATE WEBSITE✕

E-Mobility Manufacturing

Turnkey Laser Systems

Turnkey Systems for Fast Laser Processing Deployment

IPG E-Mobility systems are specifically configured for manufacturing electric vehicle batteries and power-train components. In addition to using world-leading technology and tooling, they embody IPG’s extensive knowledge of laser processes to deliver a turnkey solutions for shortest time to production. IPG works directly with end-users or with system integrators to deliver turn-key solutions ensuring a fast and seamless integration.

Optimized Design for Productivity and Quality

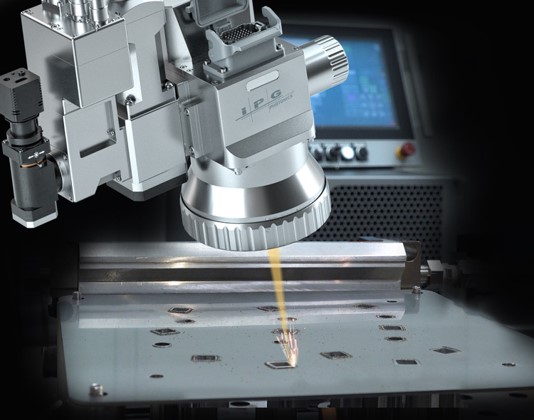

- Configured with modules selected from IPG’s industry-leading portfolio of lasers and laser processing components

- System integration optimization that benefits from all key elements being designed and built by IPG

- High-yield process development by laser specialists with specific knowledge of EV battery and automotive industries

- Customized tooling designed by in-house tooling and automation teams

- Single-vendor support for all equipment, process, and part tooling needs

IPG Process Development & Programming

- Save time and resources and let IPG laser process experts optimize your application for the best part quality and shortest cycle times

- 25 worldwide applications centers

- IPG analysis of proof of concept samples ensures the exact equipment configuration and process variables are selected to match application

- IPG engineering services are available to all Turnkey Laser System customers

The Core Components of Tooling Innovation

- A tooling team with more than 30 years of tool design experience in automotive applications

- Quantitative and analytical identification of process variations while still in the design phase

- Advanced process modeling tools like Weld Distortion Analysis (WDA) and Virtual Simulation Analysis (VSA) assess the tooling concept for production robustness

- In-depth tooling analysis informs module design when balancing module performance and manufacturability

Turnkey E-Mobility Systems

Battery Weld R&D Workstation

The Battery Weld R&D Workstation is a highly stable and precise laser processing platform for EV battery and component manufacturers needing to make proof of concept parts and perform rapid laser process development.

- Work envelope: 500 x 300 x 300 mm

- Configurable with any laser and a variety of beam delivery heads

- Same process components used for full-scale manufacturing

- Stable and precise environment allows assessment of process windows and part variables

- Turnkey system with single HMI for easy tool operation

- Conveyor feed-through option available for automated production applications

EV-Cube Busbar Welding System

The EV-Cube Busbar Welding Module is a fully-automated workstation for welding tabs and busbars in cylindrical cell modules. Configurable for either manual or conveyor-fed part loading, the system is suitable for situations where the standard equipment configuration can accelerate availability of product parts.

- Module sizes up to 1100 x 11000 x 600 mm

- High throughput for cylindrical cell welding up to 14 cells per second

- Configurable with IPG custom tooling

In addition to optimized laser, beam delivery, and IPG process programming, the available Real-time Weld depth Measurement option provides users 100% verification of penetration depth into the Li-ion cell casing.

Welding LaserCell

The Battery Welding Lasercell is a turnkey automated system configurable for a wide range of mid-power welding tasks, including Cylindrical, Prismatic and Pouch tab and busbar welding, lid and case sealing and motor hairpin welding.

- Work envelope: From 165 x 300 x 600 mm up to 1000 mm Dia, 1500 mm long

- Configurable with any IPG laser and processing head to suit the application

- Multiple part handling options to easily interface with adjacent equipment

- Turnkey system with single HMI for easy tool operation

- Configurable with IPG custom tooling

Battery Module Welding Line

The Battery Module Welding Line is a fully automated factory module for welding tabs and busbars in modules. With conveyor-fed part loading, the system is capable of handling all standard battery module sizes and is suitable for small/medium quantity production welding.

- Work envelope: 1000 x 1000 x 300 mm

- Optional flipping station for two-sided cell connections

- Optional final electrical test station with rework loop implementation

- Optional Real-time Weld measurement for ensuring battery cell integrity at the weld site

- Includes IPG custom tooling

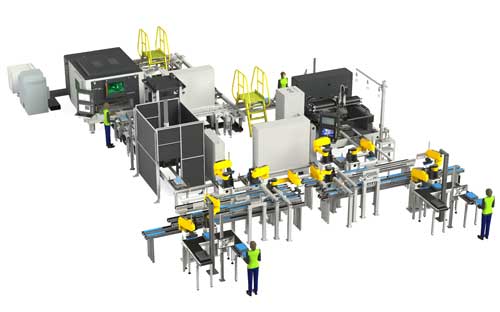

Battery Module Assembly & Manufacturing Line

The Battery Assembly and Manufacturing Line fully automates the assembly process from cell to module. With the flexibility to adapt equipment placement to suit available factory space, the manufacturing line maximizes productivity by streamlining part flow and coordination of operations.

- Process stations for cell test and load, carrier adhesive bond, busbar welding and electrical test

- Fully automated part flow within and between process modules

- Part loading stations configurable for manual loading or interfaced to customer material handling

Learn more about the Battery Module Assembly & Manufacturing Line

How Can We Help You?