View All IPG Photonics Laser Products —VISIT CORPORATE WEBSITE✕

Laser Welding Solutions for EV Battery Cells and Modules

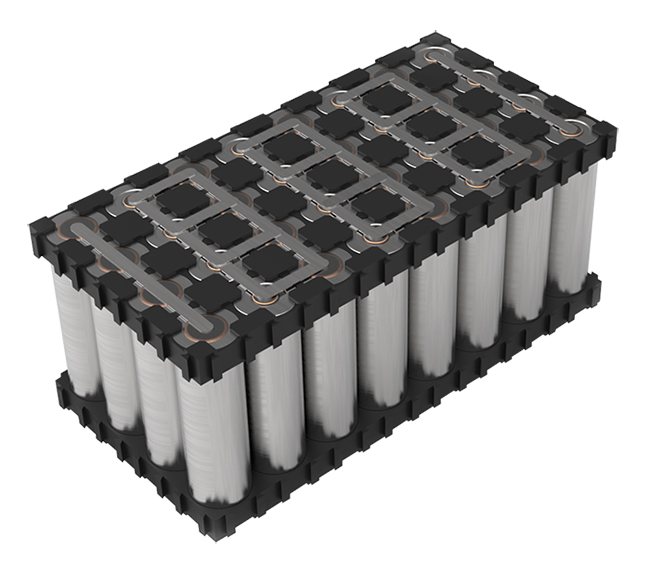

For all battery cell technologies, whether cylindrical, prismatic or pouch, conductive busbars are used to connect individual cells into modules. Laser welding enables the creation of busbar-to-cell connections that meet critically important electrical performance requirements while also offering unmatched production speed, reliability, and ease of automation.

Contact an E-Mobility expert to learn more about how IPG laser solutions can optimize your battery module production.

Laser Welding Provides Unique Benefits for EV Manufacturers

The Fastest Module Busbar Welding

Laser welding is capable of making more busbar-to-terminal welds per second than any other metal joining process, enabling manufacturers to dramatically increase module throughput.

Ultra-Consistent Welding Results

Laser welding is a non-degrading, non-contact process that produces consistent, high-quality welds across millions of busbar-to-terminal connections.

Highly Flexible Weld Joint Design

Laser parameters can be easily adjusted to match changing module production requirements such as weld size, shape, and pattern with no mechanical changes required.

Five Key Laser Welding Advantages for Battery Modules

/High-Volume-EV-Production.jpg)

1. High-Speed Production Process

The unmatched capabilities of IPG lasers, combined with systems designed specifically for battery module production, enables welding that is high-speed, high-quality, and with low heat input into sensitive components.

/AMB-No-Spatter.jpg)

2. Spatter and Porosity Virtually Eliminated

Weld spatter and porosity that can reduce busbar performance are virtually eliminated by dual beam technology that allows high welding speeds without compromising weld results.

3. Increased Part Yield from Extended Process Window

Dual beam technology has a wider selection of laser configurations than alternative technologies, allowing for greater process optimization and reduced sensitivity to variations in cell and busbar height.

/Dissimilar-Welding.jpg)

4. Dissimilar Material Welding Made Easy

Single-Mode lasers use high power density to easily join the dissimilar materials used in busbars and cell electrodes like copper, aluminum, and nickel-coated steels with minimal heat input.

/LDD.png)

5. Real-Time Weld Measurement for 100% Quality Assurance

IPG patented weld measurement technology provides highly accurate, non-destructive weld measurements on each weld as it is performed for 100% quality assurance of busbar-to-cell connections with no additional cycle time.

Discover Your E-Mobility Laser Welding Solution

IPG partners with E-Mobility manufacturers throughout the entire production process from research and development to full-scale manufacturing.

Whether you want to demonstrate feasibility with laser-processed parts or just want to bounce ideas off an experienced laser application engineer, don’t hesitate to contact us.

Fiber Laser Welding Technologies

IPG offers the most advanced fiber laser technologies, laser sources, and laser systems to optimize your battery module welding applications. Whether you need a laser tuned to your requirements or a custom production line with tooling and process recipes, IPG provides the most productive laser solutions for your E-Mobility applications.

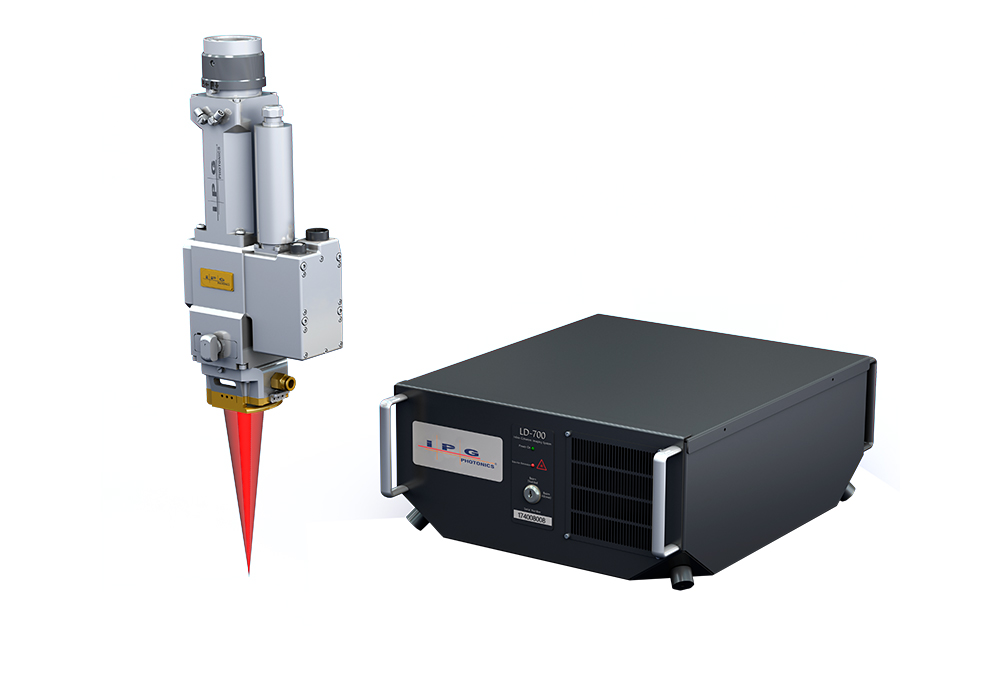

Fiber Laser Sources

for Welding

-

Dual-Beam Lasers Eliminate Spatter

-

Minimized Heat Input

-

Enables High-Speed Welding

Real-Time Laser Weld Measurement

- In-Process Laser Weld Quality Assurance

- Direct Weld Measurement

- 100% QA With No Added Cycle Time

Integrated Laser

Welding Systems (ILWS)

- Easily Integrated Laser Welding Systems

- Includes Process Development

- High-Speed, Automated Laser Welding

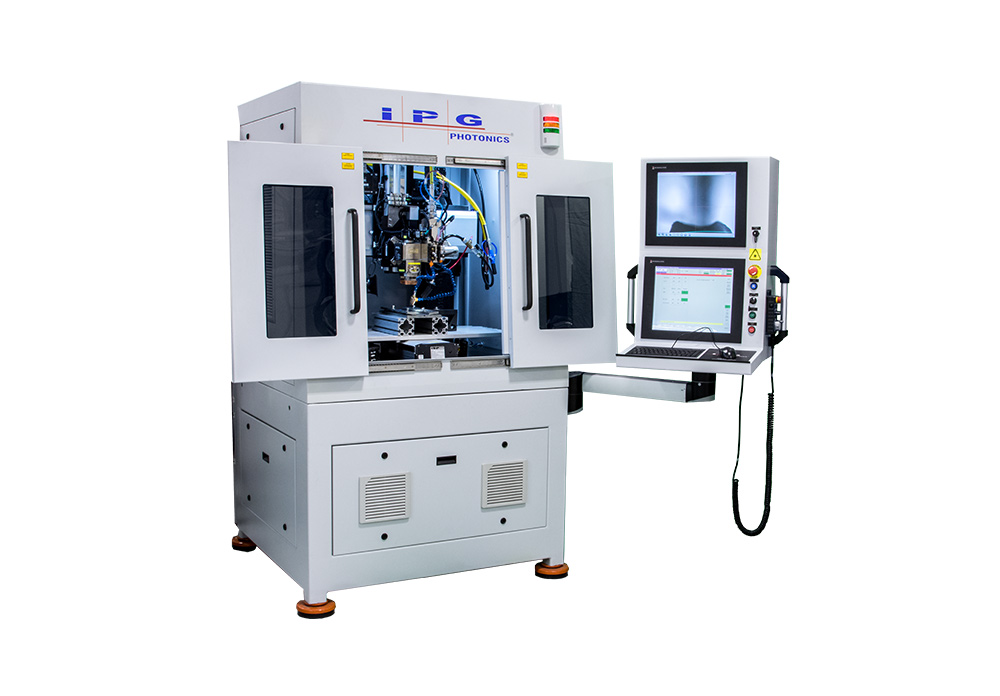

Battery Laser Welding

R & D Workstation

Precision Process Development Workstation

Work Envelope: 500 x 300 x 300 mm

Typical Applications:

- Prismatic Module Busbar Welding

- Cylindrical Module Busbar Welding

- Control Box / PDU Contact Welding

EV-Cube Laser Welding Busbar System

Cylindrical Cell Module Busbar Welding

Part Size up to 1100 x 1100 mm

Typical Configurations:

- Standard & High-Speed Configurations

- Manual Load (Pre-production)

- Conveyor Fed (Full Production)

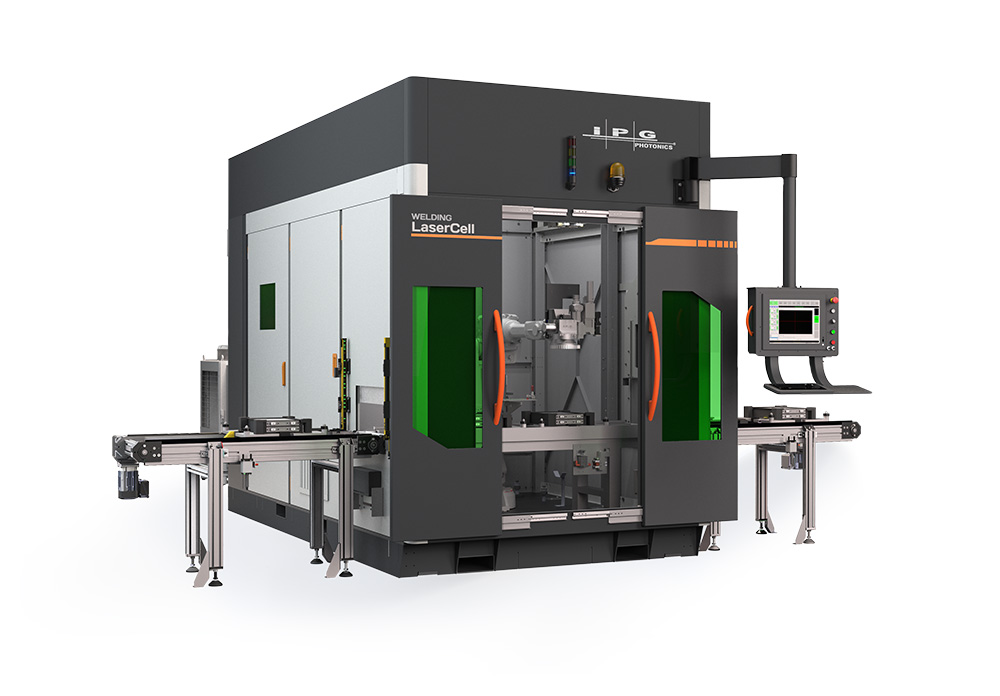

Laser Welding

LaserCell

Flexible 2D & 3D Automated Welding

Work Envelope: 1000 X 1500 mm

Typical Applications:

- Prismatic & Pouch Module Welding

- Control Module / PDU Contact Weld

- Integrated Pack & Case Welding

Battery Module

Laser Welding Line

Cylindrical Module Busbar Weld & Test Production Module

Work Envelope: 1000 x 1000 x 1000 mm

Typical Applications:

- Fully Automated Busbar Welding

- Single or Two-Sided Welding

- Post-Weld Electrical Test & Rework

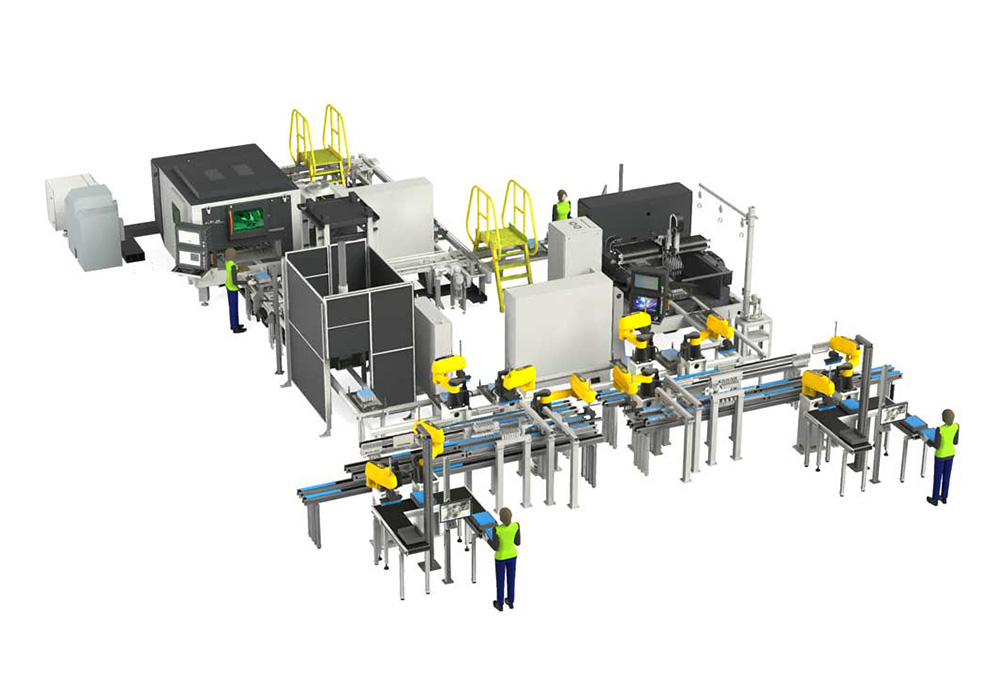

Battery Module Assembly & Manufacturing Line

Battery & Electronic Module Assembly

Fully-Automated Part Handling, Assembly, & Laser Processing

Typical Functions:

- Incoming Part Pick, Test, & Place

- Assembly / Adhesive Steps

- Laser Welding / Laser Processing

- Inspection & Electrical Test