View All IPG Photonics Laser Products —VISIT CORPORATE WEBSITE✕

Lasers for E-Mobility Applications

E-Mobility Laser Processing Products

IPG’s solutions start from off the shelf laser and beam delivery products, and can include process development, integration support, integrated system programming, and turnkey laser processing modules and systems.

IPG is pleased to invite E-Mobility customers to visit us in one of our many applications centers, and talk with us about your unique challenges. Meet us and check us out, and decide if IPG is the ideal partner to help meet your specific requirements for battery or electric vehicle production.

Lasers for Foil Cutting and Processing of Batteries

Foil cutting requirements of high edge quality, low burrs, low heat affects and high speed are best served by pulsed lasers with pulse durations in the nanosecond and picosecond ranges.

Extensive laboratory testing and production implementations have shown that cutting quality improves with cutting speed, and speed is increased by higher laser average power.

IPG YLPN lasers offer the highest power available in the industry for these applications best done with nanosecond pulsed lasers. Being entirely solid state fiber lasers they require no maintenance, and they deliver the exceptional long-term stability that IPG is known for, and that makes maintaining ongoing high manufacturing yields achievable.

For applications that are best addressed with picosecond pulsed lasers, such as when cutting foils with active electrode coatings, IPG offers a wide range of power levels to match required throughput.

Download YLPN Laser Datasheet

High-Speed Remote Laser Welding for E-Mobility Applications

Combining all the components to deliver a welding process – the laser, processing head, controller and software in an integrated package, the Integrated Laser Welding System (ILWS) solution greatly simplifies building a welding function into any production application. The optional integrated vision alignment capability reduces the demands for accurate part placement, and process development and part programming services available from IPG further reduce the demands on integrator engineering resources.

When combined with IPG’s pre-sales applications support and sample services, and the knowledge of single-vendor after-sales support worldwide, the ILWS solution can greatly accelerate and mitigate the risks for any integrated welding function deployment.

Learn more about the ILWS

Lasers for E-Mobility Welding

Because of their high performance and robustness, IR fiber lasers are the perfect choice for high-volume manufacturing operations. However, many E-Mobility applications involve copper, aluminum or alloy materials that in the solid material state have relatively low absorption of the 1070 nm IR wavelength. This is an important consideration in selecting the most appropriate laser for the specific application.

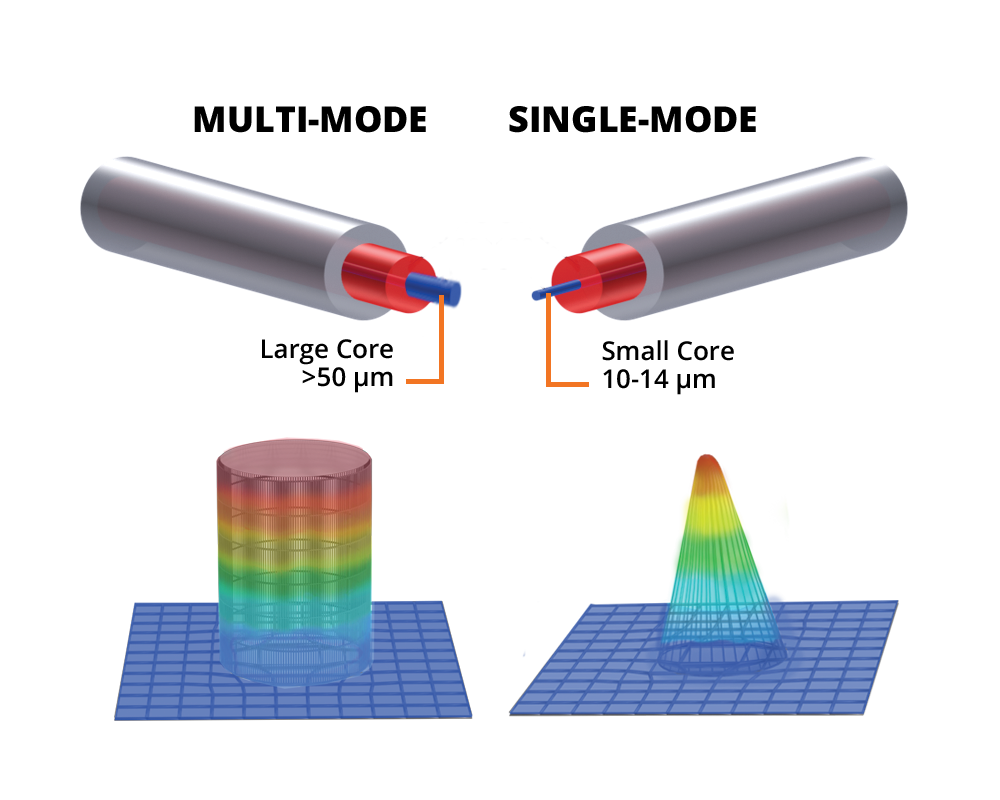

Single Mode and Multi-Mode

Many of IPG’s Laser Solutions for E-Mobility welding are based on “single mode” lasers that deliver the optical power in a smaller diameter laser spot. The increase in power density form this smaller spot not only reduces heating effects, but easily overcomes the initial lower absorption of reflective materials, allowing all the traditional benefits of the fiber laser (speed, stability and reliability) to be realized.

Adjustable Mode Beam (AMB) Lasers

Combining that single mode beam with a larger diameter ring beam in a dual-beam Adjustable Mode Beam (AMB) laser, provides a means of maintaining a larger stable weld pool that produces a low porosity, low spatter welding process. AMB lasers of this type enable laser welding of copper and allow high-quality welding to be performed at speeds much higher than can be achieved with the shorter wavelength alternates.

IPG AMB lasers are entirely solid state fiber laser sources that require no maintenance and have exceptional reliability and stability. They are available in small form-factor industrial NEMA cabinets, and unlike alternative technologies, have no mirrors or optical element alignments that create reliability concerns.

E-Mobility Applications and Laser Technology Support

Whether you need to demonstrate feasibility with laser processed parts, or just want to bounce design and implementation ideas off an experienced laser engineer – give us a call.

IPG is focused on laser technology and materials processing. It was what the company was founded on, and what drives everyone in the organization today. IPG’s mission is to make laser processing the manufacturing technology of choice, and that relies on sharing the technical knowledge so customers can make a choice.

Call and talk by phone, or better still visit one of the 24 regional applications development sites to get the information you need.

Laser Processing Heads

IPG’s vertical integration includes laser processing heads that are designed to provide the optimum materials processing results when used in combination with IPG’s fiber lasers.

The product range includes fixed beam cutting and welding heads, wobble welding heads, and a range of mid-power and high-power scanners for high-speed or remote welding or ablation applications.

The IPG scanning products are complete with scan control software and utilities for rapid programming and implementation that has functional utilities allowing seamless integrated control of laser parameters for optimized laser-material performance.

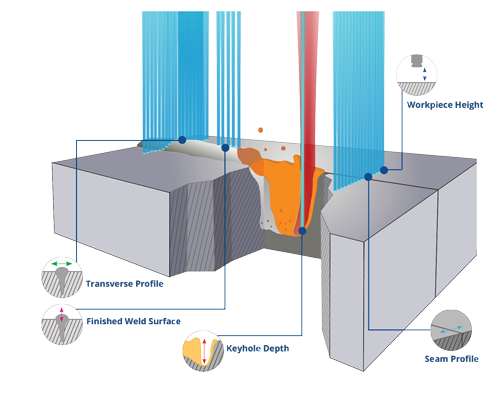

IPG’s welding process heads are compatible with the LDD-700 Real-Time Weld Measurement product.

Learn more about IPG Process Heads

Real-Time Weld Measurement

IPG’s LDD-700 Real-Time Weld Monitoring system provides the capability to monitor and improve part quality in real-time. It is a critical component in preventing and correcting e-mobility defects. Benefits include:

- Prevent latent defects and bad parts from reaching customers

- Reduce defect rates and scrap costs

- Identify and remedy defects early in the production process

- Trace the quality of every part

- Create in-place rework protocols

- Generate statistical data to control challenging processes

The LDD-700 is a proven and reliable technology for running 24/7 in high volume production environments.

Download LDD-700 Datasheet

How can we help you?

IPG has provided tens of thousands custom laser solutions around the world, and we understand that every job is unique in its own way.

Let us help you design and implement custom laser solutions for E-Mobility by drawing on our industry-leading laser materials processing and engineering expertise.