View All IPG Photonics Laser Products —VISIT CORPORATE WEBSITE✕

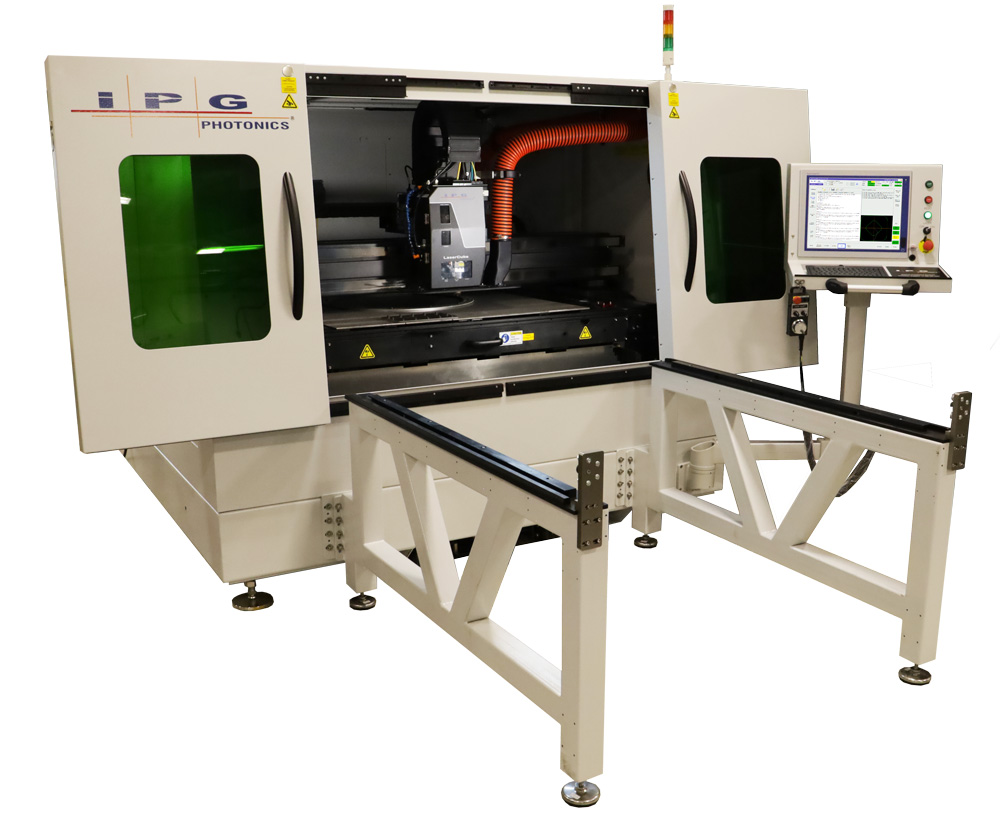

LaserCube Driller

Flat Sheet Laser Drilling Machine

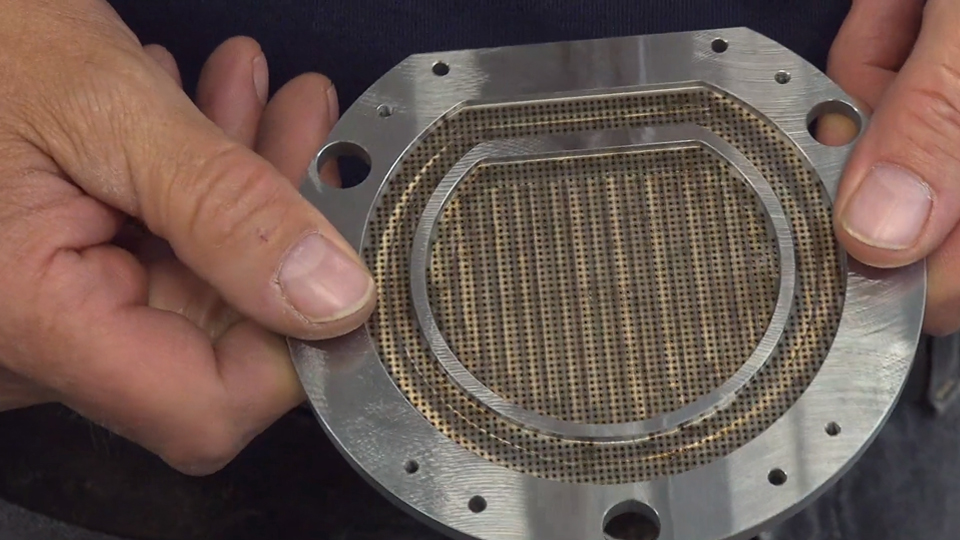

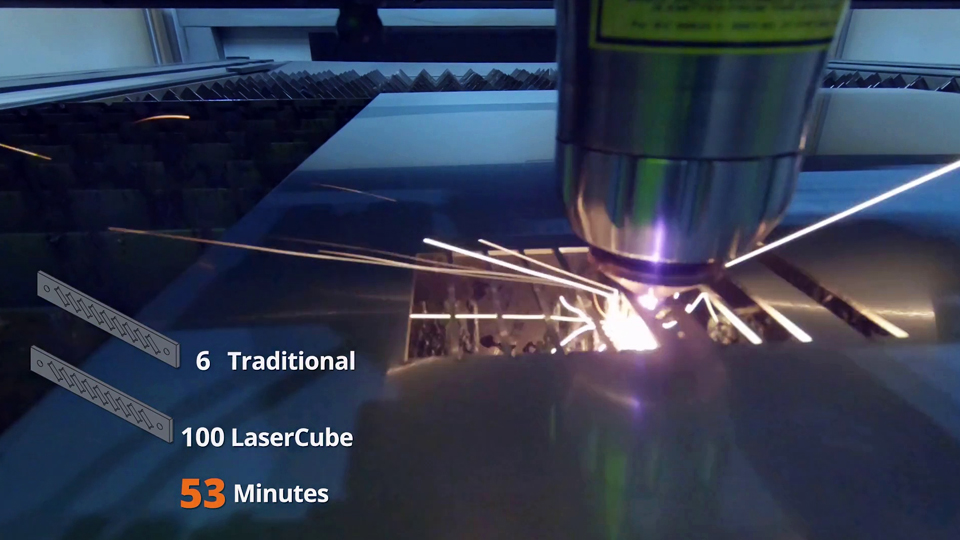

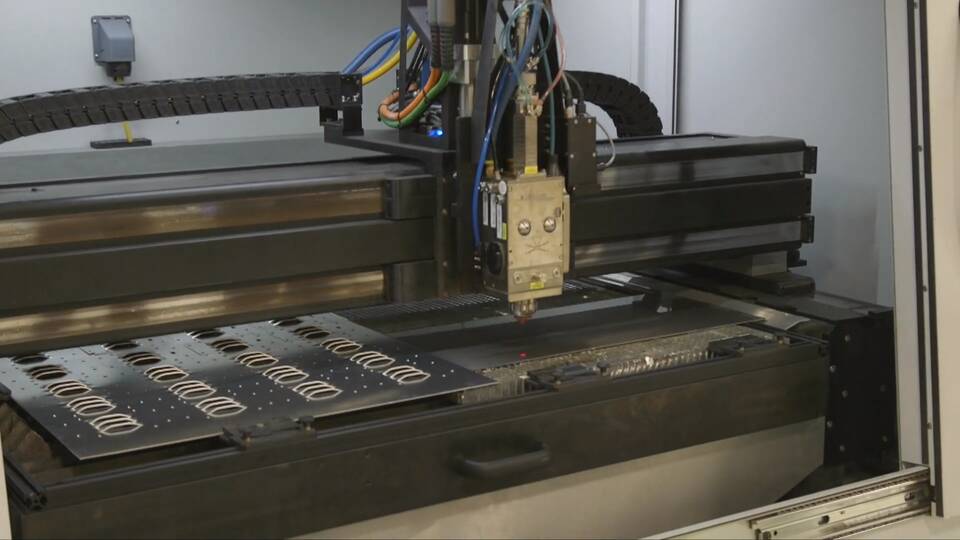

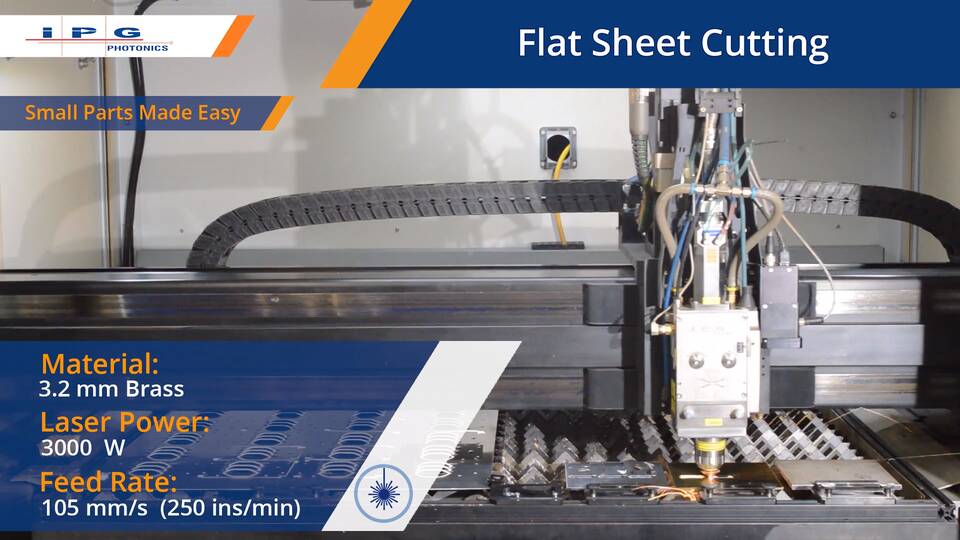

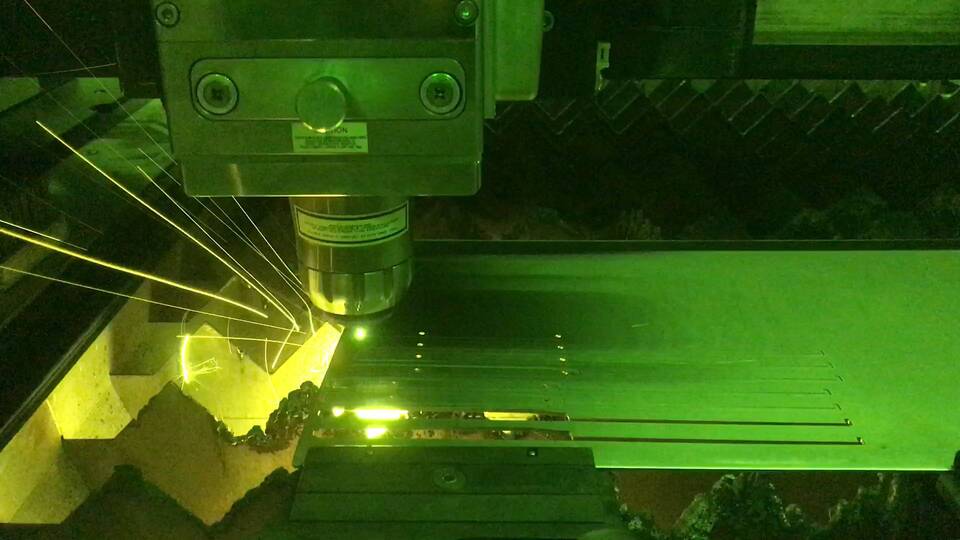

The LaserCube flatbed laser drilling system is a high-speed laser drilling machine for creating perforated metal sheets or filters comprised of thousands of uniformly spaced holes. Compared to traditional e-beam processes, Laser Drilling does not require special vacuum chambers or part coatings, and because of its lower price and smaller footprint, the LaserCube Driller produces high-quality filter parts far more cost effectively than traditional manufacturing methods

The Easy & Cost Effective Way To Make Filters

- Laser drilling is a non-contact machining process with no punches, drill bits or other parts to dull or wear

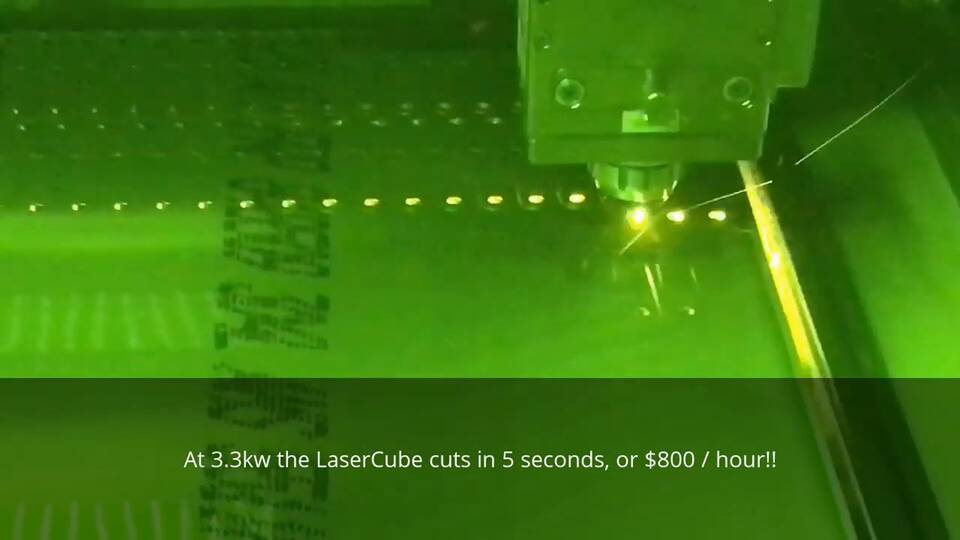

- Drill rates up to hundreds of holes per second make even large parts viable and economical

- No vacuum chambers requiring pump time

- Zero maintenance lasers and low-maintenance system design give high tool uptime and availability

- Short cycle time, high tool utilization, and small equipment footprint combine to give lowest overall cost-per-filter part

Download Datasheet

"Fiber laser reliability and ease of use combined with the small footprint and standard facilities requirements makes this one of the easiest machining tools to install"

Simple and Flexible Laser Drilling Machine

- Small Footprint – Laser mounts inside workstation

- High-speed drilling – Easy switch over between part designs

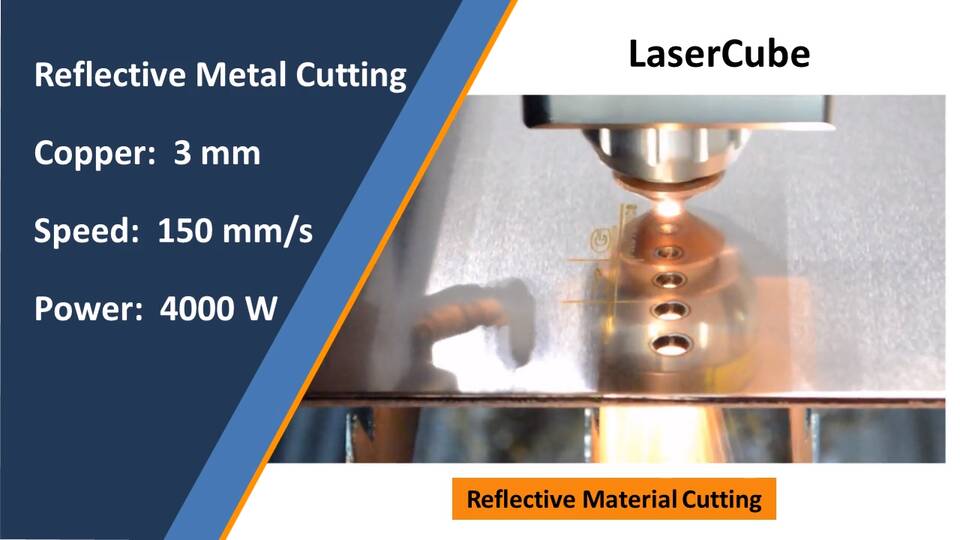

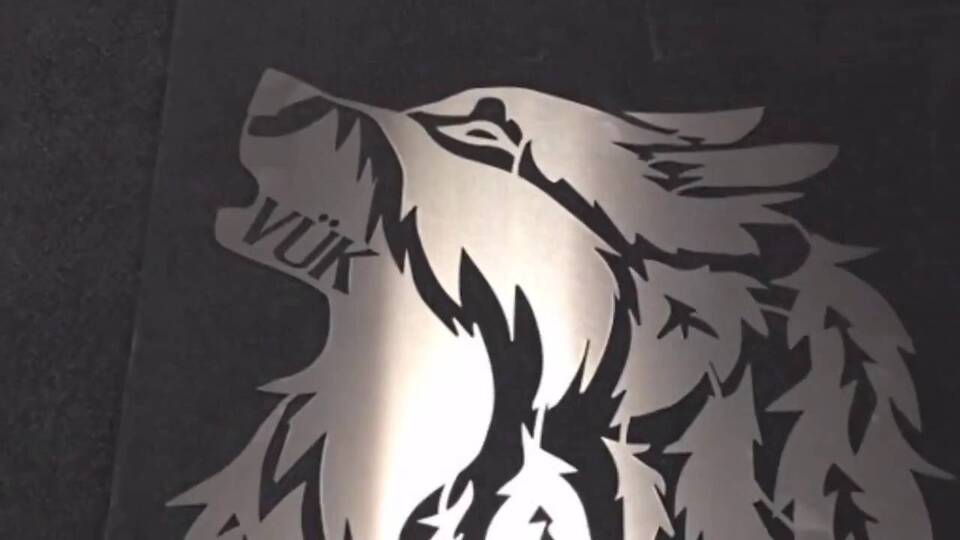

- Compatible with all metal types – even magnetic materials

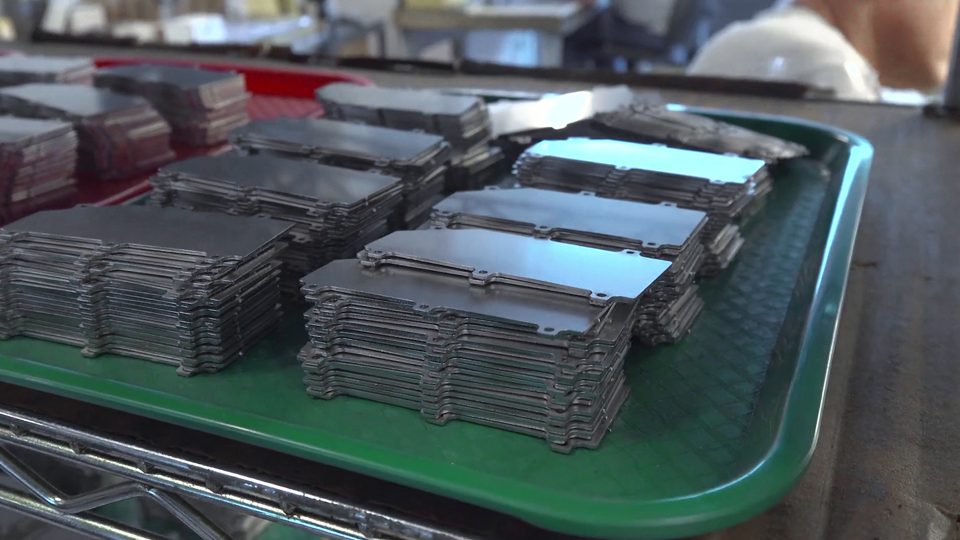

- Additional programmable cutting function to cut out completed filter or singulate smaller filters from a multi-part sheet

- Integrated tooling plate and mechanical clamps minimize requirements for individual part tooling

- Easy to install and operate

Transform Filter Production

OEM equipment makers, after-market job shop filter suppliers and industrial users with high consumptions of perforated metal filters, all can reduce filter-related costs with the LaserCube Driller.

Requiring minimum floorspace and only compressed air and electricity as utilities, the LaserCube Driller makes filter drilling easy and affordable and provides a cost-effective alternative for filter supplies.

IPG Fiber Lasers Enable High Speed Drilling

- IPG high-brightness and high peak power fiber lasers provide efficient laser drilling

-

Highly focusable 1070 nm laser beam couples easily and drills fast, even on reflective metals

-

Compact laser packaging allows the laser source to be mounted within the drilling workstation

- Zero-maintenance – no gases to replace, no mirrors to align, no consumables and no downtime

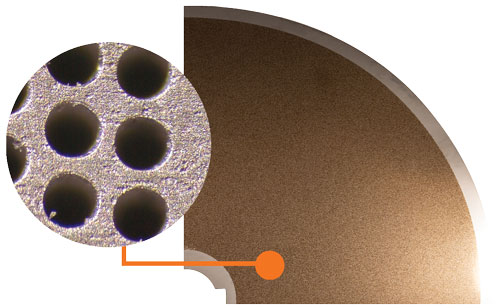

High-Accuracy Drilling for High-Quality Parts

-

Drilled hole sizes from 80 to 300 µm diameter on filter parts up to 1000 x 1000 mm size

- Natural granite base provides stiffness and stability for precision part processing

- Synchronized laser firing and part positioning provide hole positional accuracy and high array uniformity

- Automatic height calibration and exceptional laser beam power stability result in hole size variations < 5%

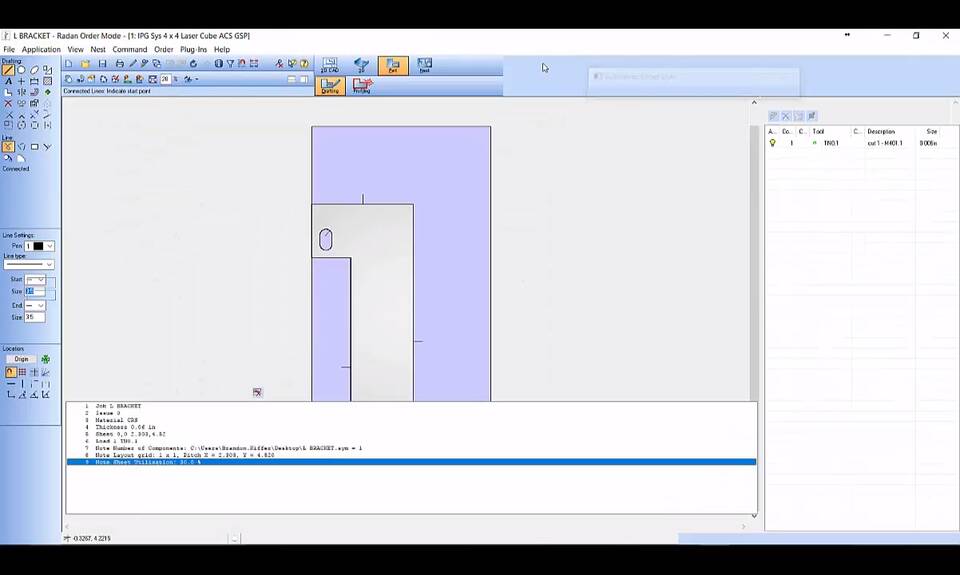

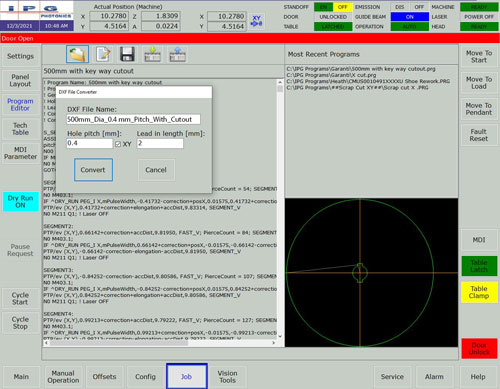

Simple Operation and Part Programming

- Preset program recipes for typical material / thickness / hole type combinations

- Simple CAD file input defines part cutout lines and regions containing drilled holes

- Allows either large single-part or nested smaller part layouts

- Single input of hole-to-hole spacing distance enables automatic generation of drilling job file

- Recall of stored job files for fast repeat part processing

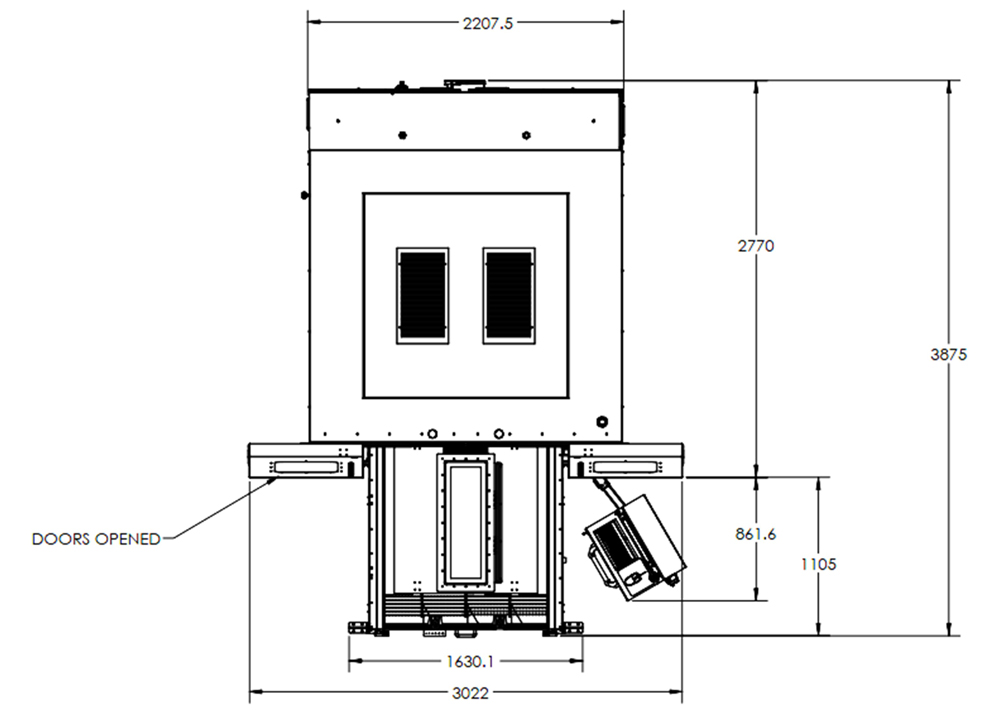

Small Footprint

LaserCube Driller is a highly productive system that produces parts up to 1 m in diameter, while having a footprint of only 3.0 x 3.9 m

- No additional space needed for electronic racks, vacuum load locks or vacuum pumps

- Laser sources fits inside workstation

- Extendable/retractable table for easy sheet loading

- Easily installed in typical manufacturing environments

High Reliability & High Availability

The LaserCube Driller is designed for maximum reliability and minimal preventive maintenance – maximizing the time available to drill production parts.

- Zero-maintenance IPG fiber laser

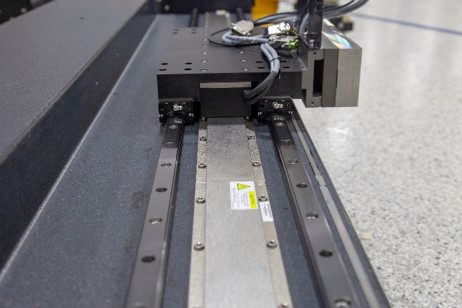

- Direct drive linear motors with no parts to wear or replace

- Open atmosphere processing with no vacuum systems

| Laser Type |

IPG CW or Drilling Fiber Laser matched to application requirements |

|

Maximum Part Size |

1250 (X) x 1250 (Y) x 75 (Z) mm |

|

Drilling/Cutting work envelope |

1000 (X) x 1000 (Y) x 70 (Z) mm Telescoping Drawer with Metal Saw Tooth Cutting Points; Honeycomb Inserts (optional), Removable Debris Collection Bin; 91 kg Load Capacity |

|

Motion Platform |

Linear stage, H Gantry 1.micron linear encoders Max Velocity (X,Y): 1000 mm/s, Max Acceleration 1 G |

|

Beam Delivery |

IPG Sealed Enclosure Motorized Laser Processing Head. Optics to suit application |

|

Electronics |

Industrial Motion Controller with touchscreen Panel PC. EtherCat I/O 5-Axis Jog Pendant. |

|

HMI Features |

Program input page for part processing Technology Database to store process recipes for drilling, cutting and piercing |

|

Pneumatics |

Process Gas Package for O2, N2 and Air – electronically settable Clean Dry Air (CDA) panel. Regulated pressures for system services |

|

Drilling Pallet |

Tooling plate to support large drilling area. Mechanical pat clamping to resist process-induces stresses Set-up area for process development |

|

Drilling Performance (Subject to laser selection) |

Hexagonal or linear aligned holes Drilled hole sizes: 80-300 micron diameter (Entrance) Hole size variation: < 5% of hole diameter Hole pitch variation: ±10 micron Material thickness: 1-2 mm typical Hole drilling rate: 10 – 300 holes/sec |

Technical Literature

Videos

Laser Welding Options & Accessories

In addition to the standard X-Y-Z axes and laser process head, there are several optional modules and accessories that may optimize the functionality of the system in your specific application. The most popular options are indicated below. Please contact IPG directly if you have additional requirements.

Direct Drive Rotary Stage

High-precision, high-speed rotary stage with continuous motion synchronized to X-Y-Z axes

Servo-driven rotary stage

- Brushless direct drive.

- Travel +/- 360° continuous

- Rotation speed: 600 rpm max

- Accuracy: 10 arc-sec

- Bi-directional repeatability: 4 arc-sec

- Pneumatic ER25 Collet Chuck

- Includes an additional axis of motion control

Sheet Autoloader

Fully automated sheet load/unload module for full-shift unattended operation

Flexible Sheet Size: 24 x 24 up to 48 x 48 inch

- Flexible Sheet Thickness: 0.20 up to 0.25 inch

- Sheet Stack Height up to 7” max. (# sheets x thickness): Range: 350 x 0.02” to 28 x 0.25”

- Load Time: <75 seconds (Sheet exchange)

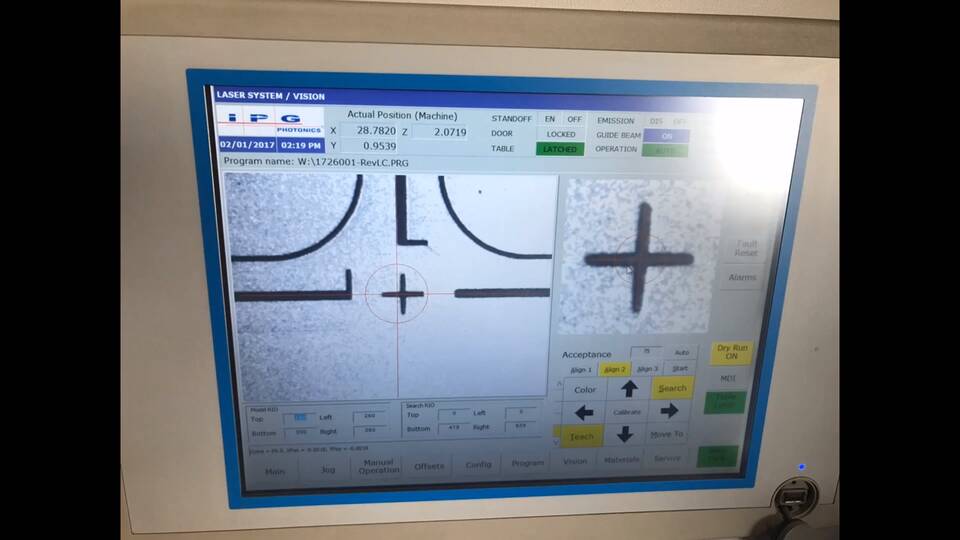

Machine Vision

Digital video camera, illuminator assembly and integrated software to visually align and inspect parts under the control of the HMI software. Standard routines allow for automated modification of laser cutting position for compatibility with pre-punched, printed or fiducially marked workpiece.

Option includes 90 fps digital camera, controllable illumination system and integrated software

- Image field of view ~ 12 x 10 mm

- Alignment feature requirements. Any feature 1 to 3 mm in size that is unique within the 12 x 10 mm field

- Powerful HMI capabilities for generating a matrix of part positions and teaching feature recognition and fiducial positions

- Corrections include: Position offset, rotation and scaling (4-point alignment) with typically 10 µm (0.0004 inch) accuracy.

Dust Collector

- 4-cartridge downflow dust collector:

- Holds 4 cartridge filters totaling 1,016 f of filter media

- 5 HP integrated fan rated for 2,000 CFM @ 10”

- Noise attenuation enclosure

- Integrated cyclonic spark trap

- Nano-Fiber filter media with Merv 15 efficiency

- Reverse pulse filter cleaning system

- Pulse control timer board with built-in digital pressure gage

- Goyen solenoid and diaphragm valves

- Dual dust drawer collection bins

- Easy access door, with stainless steel components

- Heavy Duty 7 and 10 gage steel construction

- 5-year manufacturer’s materials and craftsmanship warranty

- All-in-one starter/disconnect/timer board/digital pressure gage (460V)

- Pre-wired to motor and solenoid valves

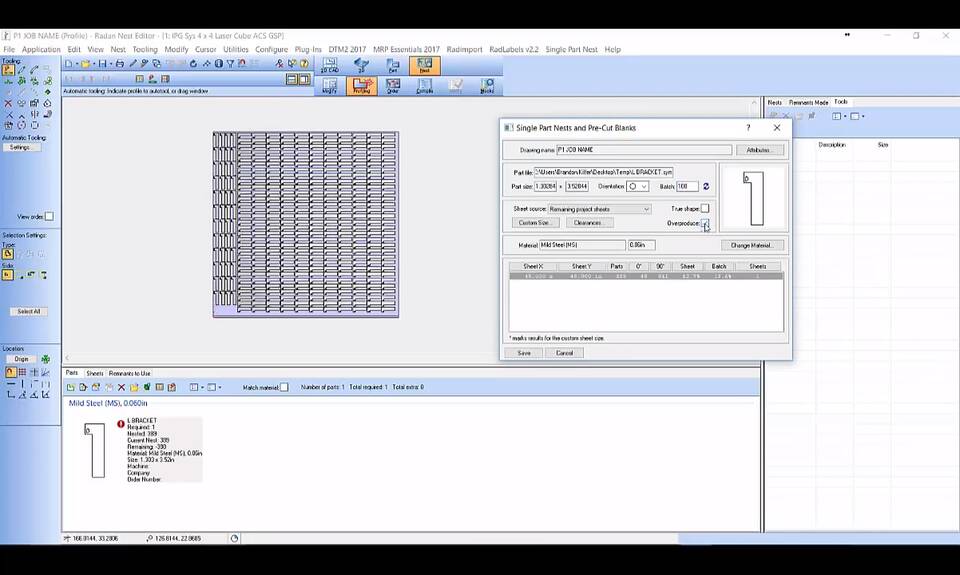

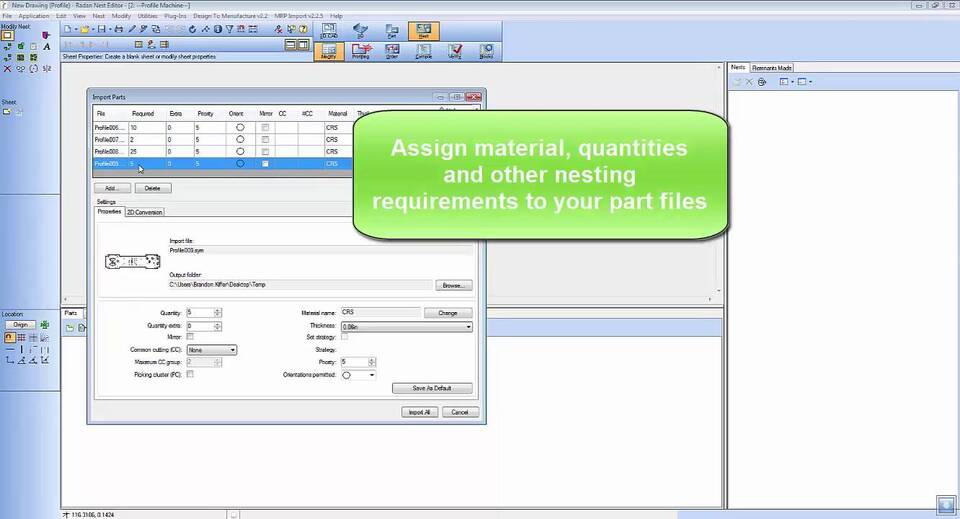

CAD/CAM Package

SigmaNEST CAD/CAM package is an optional software product used for converting CAD drawings into part programs.

- Functionality includes advanced nesting, cut sequencing, feature avoidance, and material library features to maximize the efficiency and throughput of your system.

Automatic Doors

Pneumatic actuator to automate slide door which can be controlled via HMI software or G-code.

LaserCube Software

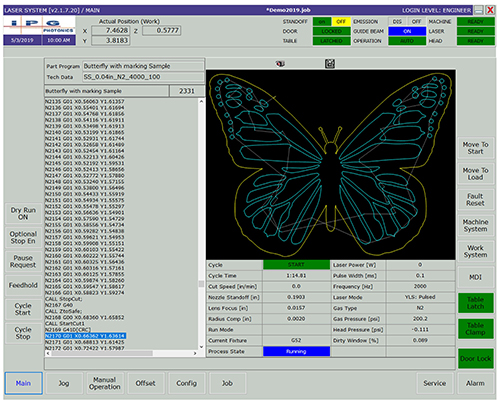

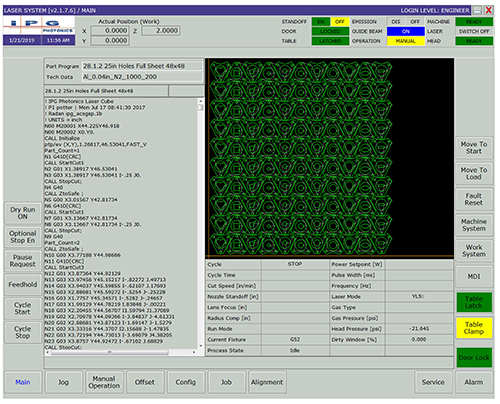

The software that runs the LaserCube is a customized application called HMI2 (Human Machine Interface-2) that runs as a Microsoft Windows® 10 application. It is preloaded and tested at the IPG factory and resides in the workstation’s hard drive.

Used in combination with standard G-code programming, its capabilities provide the user with a comprehensive, easy-to-use programming and operator interface.

Easy-to-Use Programming and Operator Interface

- Fully integrated control of laser, motion systems, beam, delivery, process control modules and vision functions

- Live G/M code display with production controls for interrupt and resume

- Graphical display showing cuts to be made

- Stored, editable, library of cutting parameter tables for a wide variety of materials

- Automated machine-vision based alignment and nested job setup

- On-machine part nesting for arrayed parts

- Powerful, simple to operate, vision alignment software for combo part processing

How Can We Help You?