Blog

Surface Preparation with IPG Pulsed Lasers

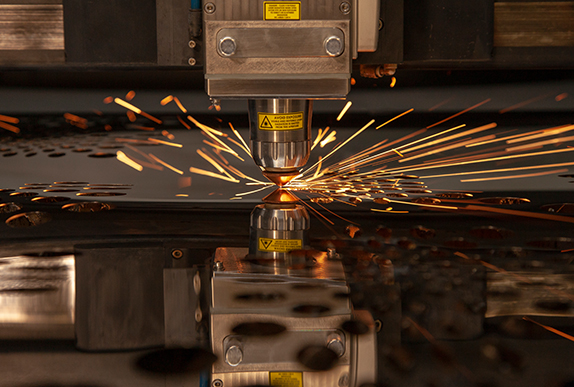

Laser cleaning and surface preparation is a booming application for IPG’s pulsed lasers as customers continue to search for enhancements to manufacturing quality and efficiency. Laser surface preparation is an ablative process whereby laser energy is focused and absorbed by the surface to produce favorable modifications. Applications include the removal of paint, adhesives, oxides, oils, and mold release from metal, glass, and composite substrates. In addition to material removal, laser texturing of the surface plane is also used to improve the strength and reproduceability of adhesive bonding in applications ranging from painting to creating strong, reliable mechanical joints for automobiles or heavy industrial equipment. Lasers displace traditional processes like abrasive blasting, CO2 dry ice blasting, wet chemical baths and manual grinding/sanding in the aerospace, automotive, and heavy manufacturing industries by improving cost and quality while offering an environmentally friendly process.

In addition to the visual observations, various analytical tools are used to measure surface contact angle or identify chemical characterization of the sample. The SEM/ EDS analysis of the weld above shows a large reduction in carbon and oxygen as a result of removing oxides and other surface contaminants. Minute traces of sodium, potassium, and chlorine disappeared after cleaning.

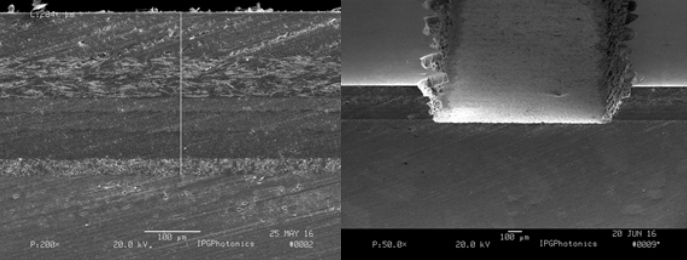

Paint removal applications come in many different forms. The two SEM images (above) are cross sections of a painted aluminum alloy before and after laser paint removal. The left hand figure shows a 300 μm thick paint stack on an aluminum substrate of 75 μm clear coat, 75 μm blue coat, 100 μm white coat and 50 μm primer coat. The figure on the right shows the processed sample with all layers removed down to the aluminum.

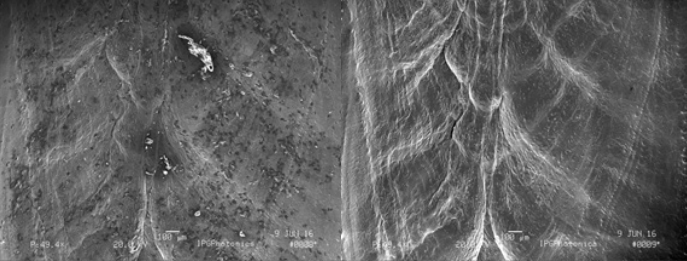

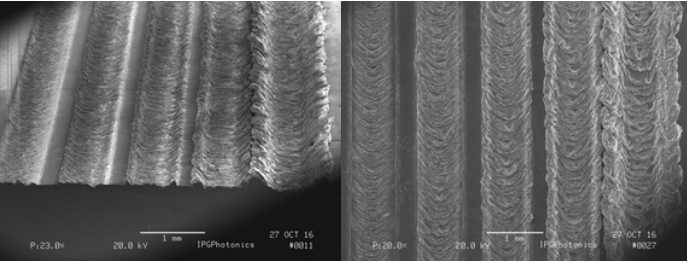

Surface texturing can impart various characteristics to the treated metal. Texturing can be cosmetic or promote a subsequent process such as bonding and joining. The figures above show five textured areas on an aluminum 6061-T5 alloy. The laser texturing has the dual benefit of cleaning the surface while providing mechanical keying to enhance subsequent adhesive bonding.

Learn More About Laser Cleaning

Surface Cleaning

Surface cleaning is an easy application that is often served by a large spot, low pulse energy at high scan speed. If machine oils and incidental surface contamination are the targets, a large spot with minimal pulse and line overlaps can quickly clean lightly contaminated surfaces. This technique is especially helpful when cleaning incidental oils, grime commonly associated with metals received with a standard mill finish.

The figures above show stainless steel pipe sections welded together before and after cleaning. The weld process on uncleaned sections produces a heat affected zone, which in turn causes the discoloration (caused by the oxidation) over the surface adjacent to the laser weld (above left). The cosmetic appearance was improved via laser ablation (above right).

In addition to the visual observations, various analytical tools are used to measure surface contact angle or identify chemical characterization of the sample. The SEM/ EDS analysis of the weld above shows a large reduction in carbon and oxygen as a result of removing oxides and other surface contaminants. Minute traces of sodium, potassium, and chlorine disappeared after cleaning.

Paint Removal

Paint removal applications come in many different forms. The two SEM images (above) are cross sections of a painted aluminum alloy before and after laser paint removal. The left hand figure shows a 300 μm thick paint stack on an aluminum substrate of 75 μm clear coat, 75 μm blue coat, 100 μm white coat and 50 μm primer coat. The figure on the right shows the processed sample with all layers removed down to the aluminum.

Surface Texturing

Surface texturing can impart various characteristics to the treated metal. Texturing can be cosmetic or promote a subsequent process such as bonding and joining. The figures above show five textured areas on an aluminum 6061-T5 alloy. The laser texturing has the dual benefit of cleaning the surface while providing mechanical keying to enhance subsequent adhesive bonding.

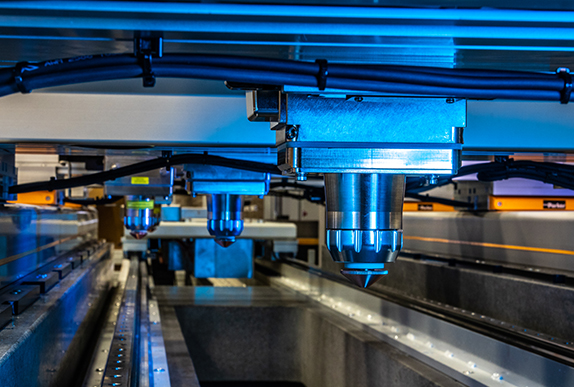

IPG’s Laser Cleaning Systems

IPG Photonics manufactures several integrated laser cleaning systems that take advanced of our high power pulsed fiber laser technology. The Scanning Laser Workstation is a compact multi-axis system ideal for surface preparation of small parts typically found in the medical device and electronics industries. R&D and advanced processing environments can take advantage of the IX-280 Series, which can be equipped with either one or two lasers for maximum precision. The IX-255 is a highly flexible UV laser micromachining system used by the LED manufacturing industry for the separation of sapphire carriers from the GaN active devices.