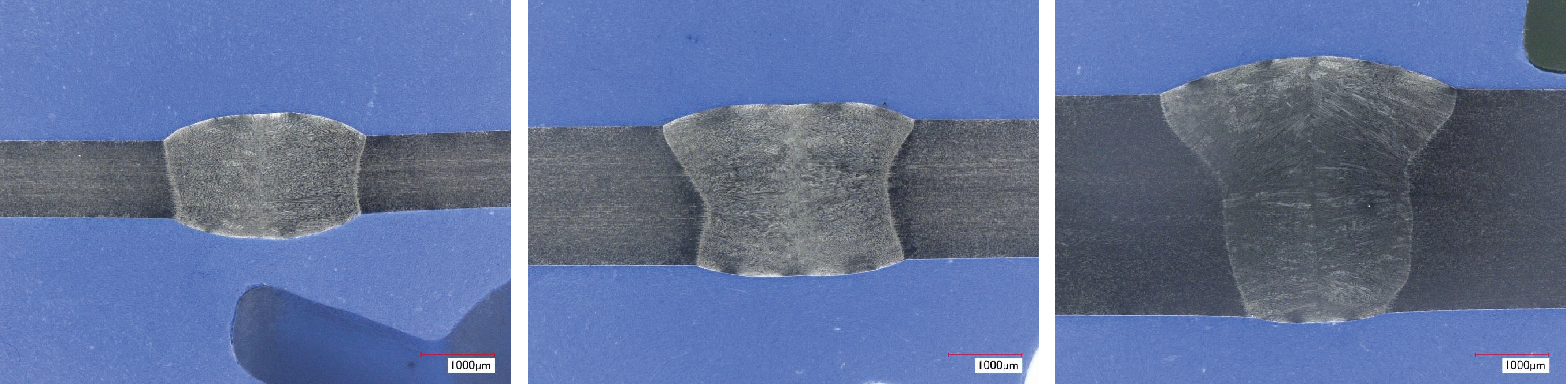

Butt joints in 304 stainless steel plates of 0.036 in Butt joints in 304 stainless steel plates of 0.075 in Butt joints in 304 stainless steel plates of 0.120 in

In all cases, no cracking, incomplete fusion, porosity, inclusions, or other defects were noted during weld tests for butt joints in 304 stainless steel plates of 0.036 in., 0.075 in., and 0.120 in. The weld profiles passed all tests and no underfill was noted.

The findings from the third-party evaluation of the samples by Sturbridge Metallurgical Services indicate that LightWELD produces welds that meet rigorous industry standards, including critical aerospace applications; offering both efficiency and quality in welding applications. In summary, LightWELD offers a faster and more efficient welding solution compared to traditional MiG and TiG techniques, thanks to its high power density that enables deep penetration and faster welding speeds. Furthermore, when parts fit up well, filler wire can even be eliminated, resulting in an aesthetically pleasing and strong weld.

LEARN MORE ABOUT LIGHTWELD