View All IPG Photonics Laser Products —VISIT CORPORATE WEBSITE✕

Laser Cleaning & Coating Removal

Laser ablation, commonly referred to as laser cleaning, is a proven method for surface cleaning and preparation, coating removal, and surface roughness modification for manufacturing, refurbishment, and repair applications. Laser cleaning is fast, repeatable, and eliminates the need for abrasive grits and chemicals, and drastically reduces solid waste.

Typical Laser Cleaning Applications

- Rust & Oxidation Removal

- Paint Stripping/Removal

- Oil & Grease Removal

- Surface Preparation

- Post-Weld Cleaning

- Cleaning of molds

- Part Cleaning for Repair

Get a Free Application Evaluation

"Advances in laser technology and the availability of laser ablation systems, have significantly increased production capacity and are a lower-cost, greener process."

Benefits of Laser Cleaning

Laser Cleaning is an Eco-Friendly Process

-

Laser ablation eliminates chemical consumables and subsequent disposal challenges

-

Drastically reduces the amount of toxic waste to meet OSHA & EPA regulations

-

Reduces overall costs by utilizing a green process that does not require expensive disposal of hazardous materials

Laser Cleaning is Precise and Highly Controllable

- High-throughput process that consistently cleans parts with no surface contamination or degradation

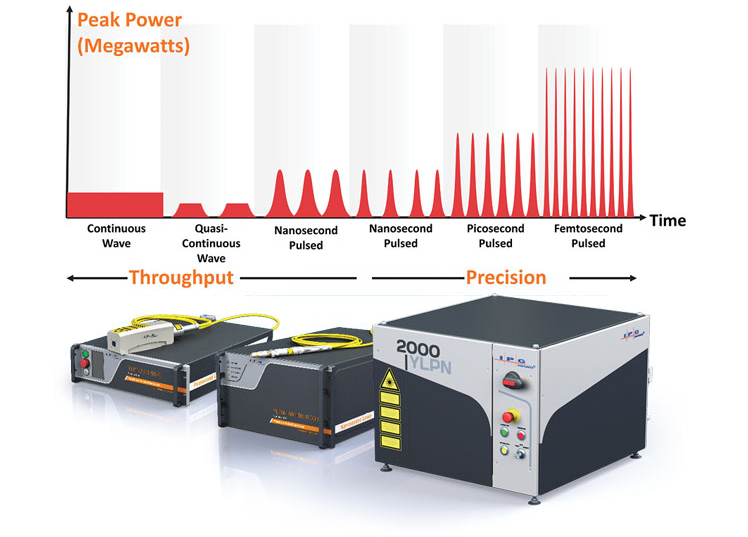

- Benefit from having total control of the cleaning process by matching laser types to specific applications

- Flexible laser cleaning systems are adjustable to remove surface contaminants or coatings while controlling the effect on the material surface

Laser Cleaning is a High-Speed &

High-Productivity Process

- Faster and more consistent than traditional cleaning methods

- Even faster cleaning is realized with customization of the laser parameters to best match specific application

- Match cleaning capacity to manufacturing load and minimize cycle times

Laser Cleaning is Repeatable & Easily Automated

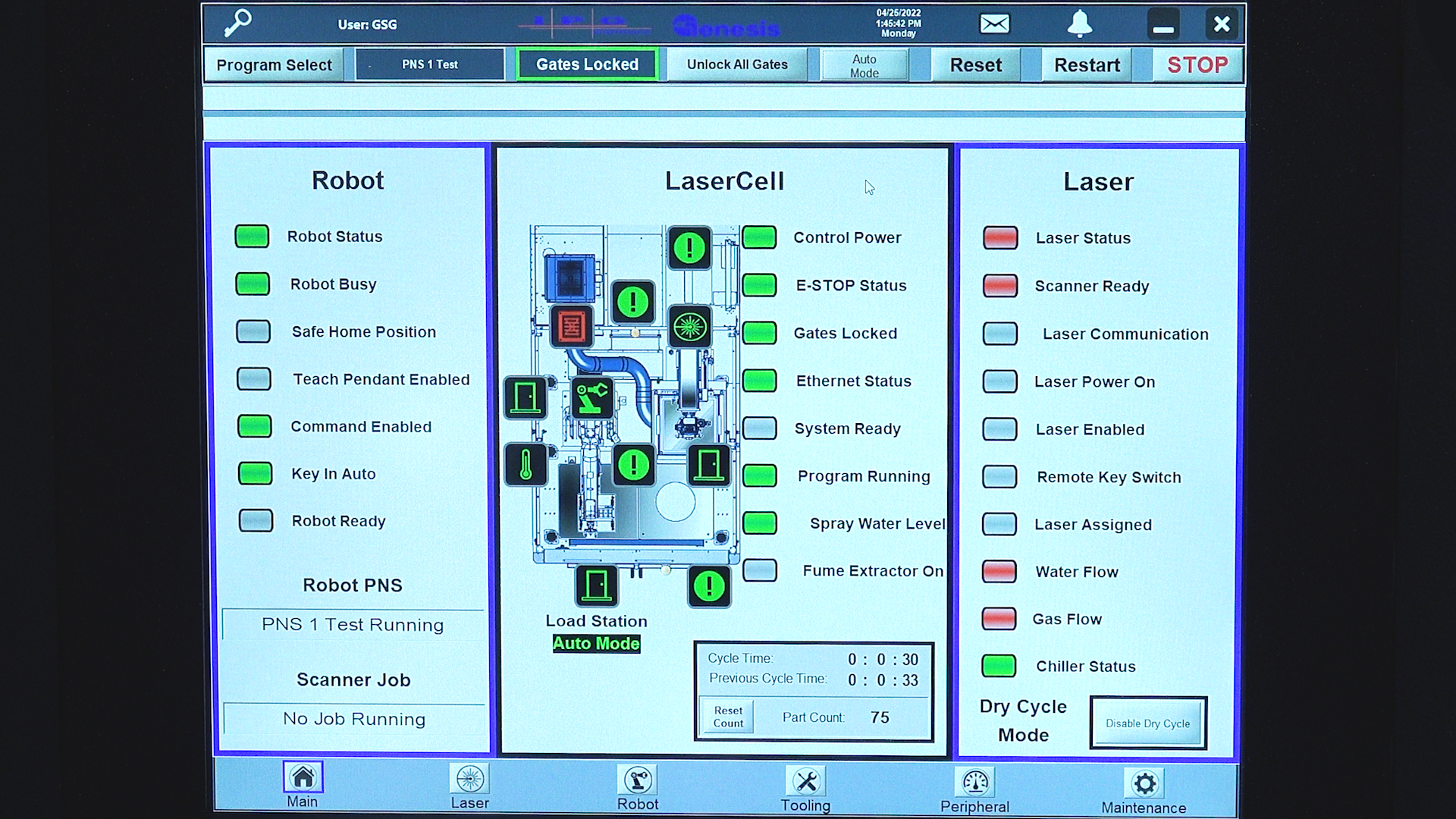

- Laser ablation systems are easily programmed and do not require highly-skilled manufacturing personnel

- Built-in libraries of laser cleaning processes are designed and optimized to dramatically reduce rework cycles

- Long-term power stability of fiber laser sources provide highly-repeatable processing

IPG Engineering Optimizes Laser Cleaning Processes

- IPG Application Engineers develop optimized processes to achieve high quality results, lower operating costs and increase productivity.

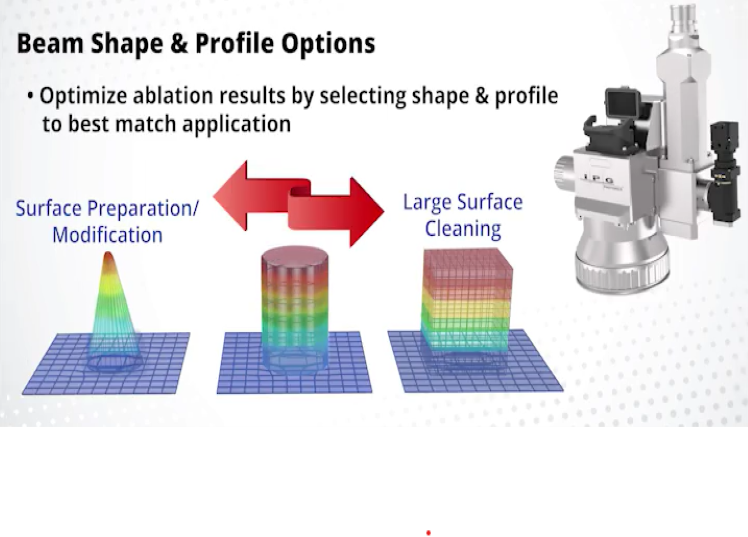

- IPG Application Engineers select laser and beam delivery for the ablation application to ensure process effectiveness.

- For surface preparation, a cone-shaped beam works best for high-intensity, highly-concentrated ablation

- For cleaning larger areas with best process uniformity, a round/square beam with a flat energy profile is ideal

Why IPG?

IPG offers the widest range of fiber lasers with greater output powers, wavelengths, modes of operation, and flexible beam delivery at a much lower investment than competing technologies. IPG fiber lasers are entirely solid state, zero maintenence, and maintain levels of reliability not traditionally seen in laser ablation applications. IPG fiber lasers are up to 10X more energy efficient than legacy lasers. IPG fiber lasers are the industry standard and the product of choice in industrial material processing applications

Laser Cleaning Questions and Evaluations

While IPG has provided tens of thousands material processing solutions around the world, we understand that every job is unique in its own way. We also know that before investing in a solution, it only makes sense to ensure that a laser system can meet your application and organizational needs.

Complete this form to reach out to our team with your specific laser cleaning requirements.

Application Evaluation

Laser Cleaning Systems

- Application

Cleaning/Ablation - Work Volume

165 x 300 x 600 mm - Part Loading

9 options - Laser Power

Up to 12000 W - System Footprint

4200 x 2200 x 3000 mm

- Application

Cleaning/Ablation - Work Volume

500 x 300 x 300 mm - Part Loading

Custom interfaces - Laser Power

Up to 1000 W - System Footprint

1220 x 915 x 2110 mm

- Application

Cleaning/Ablation - Work Volume

500 x 300 x 300 mm - Part Loading

Manual load only - Laser Power

Up to 6000 W - System Footprint

1600 x 1300 x 2200 mm

- Application

Cleaning/Ablation - Work Volume

250 x 250 x 200 mm - Part Loading

Manual load only - Laser Power

Up to 6000 W - System Footprint

1240 x 840 x 2240 mm