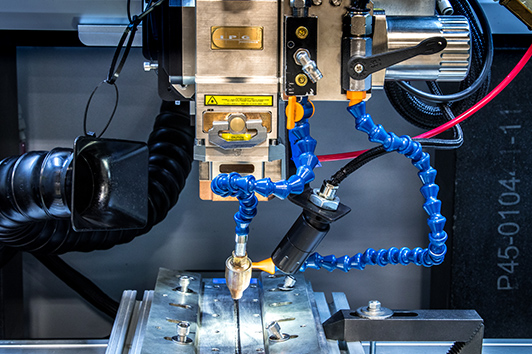

Laser Scanning Heads for Remote Welding, Cutting and Surface Cleaning

IPG scanners are characterized by having the highest laser power handling in their class. With designs that optimize the beam quality and spot size of the IPG lasers, the scanners deliver maximum machining capabilities for the user.

Scanners are configurable with a wide range of collimator and focus lens options (that determine spot sizes and working distances) allowing your IPG laser system to be perfectly matched to the application. Having both through-lens and off-axis vision options available on the scanner enables easy accommodation of imaging requirements of the systems in which they are used.

For laser welding applications, the 2D High-power Scanner can be paired with the LDD real-time laser weld measurement system for the ultimate weld quality process control

Download Scanning Head Brochure